While setting up 60,000 USD $ organic fertilizer production plant, there are many aspects you should consider. According to our years of experience, you should note the following four factors. They are raw materials selection, organic fertilizer type selection, production process and fertilizer machines selection. Here are some tips for you. You can know the detailed information about them from the following.

In order to produce the fertilizers with stronger competitiveness, you need select the high quality organic waste for the $60,000 organic fertilizer production plant. Generally speaking, there are many types of the raw materials that can be used for producing the organic fertilizer. According to the amount of the raw materials the organic fertilizer manufacturers use, there are two main types of the organic waste. One is the main materials, the other is subsidiary materials.

Nitrogen, phosphorus and potassium are the three most needed elements in the growth of crops. The reason why some materials can be used as the main materials is that these materials contain a lot of these three elements needed for plant growth. Generally, the main organic materials you use will account for 30%-80% of all materials when producing the organic fertilizer. You can use the animal manure as main materials. But what types of the animal manure do you need collect? You can learn more from the following information.

When making the organic fertilizer, you can adjust the moisture, C/N, pH of the materials by adding the subsidiary materials into the organic wastes. What are the subsidiary materials? The agricultural waste we often see such as straw, wheat bran and so on can be used as the organic fertilizer production accessory. But you’d better use the organic fertilizer crusher to grind the agriculture waste before add them into the material stack.

The materials mentioned above are just for the reference only. You can also make the survey about the local organic fertilizer consumption market soil conditions, the type of plants grown locally, and the nutrients needed for plants at different stages of growth. Then you can prepare the organic waste for the $60,000 organic fertilizer production plant according to the results of the investigation.

What Fertilizer Type Can You Choose For The $60,000 Organic Fertilizer Production Plant

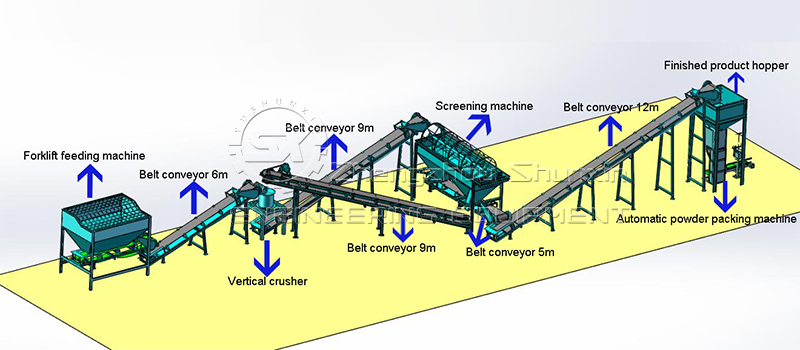

In the organic fertilizer sales market, there are organic fertilizers of different shapes. Organic fertilizers with different shapes have different onset time and action time. For example, powder fertilizer has a quick effect. However, the powder organic fertilizer has the characteristic of volatility. Therefore, the powder organic fertilizer has a short effective time. Granular organic fertilizer takes effect slowly and has long-time effect. Organic fertilizers with different shapes also have different effects on crops. For the $60,000 organic fertilizer production plant, we suggest that you produce the powder one. Because you will invest more to deploy the production equipment while making the granular fertilizer. In contrast, you will need less production equipment when building the powder organic fertilizer production line. Furthermore, the powder organic fertilizer making process is very simple. You can master it quickly.

The powder organic fertilizer manufacturing process can be divided into five steps. The process are as follows.

You can know about the specific details about each powder organic fertilizer production process by reading the following content. And you can also know what type production equipment is suitable for the $60,000 organic fertilizer production plant.

For The $60,000 Organic Fertilizer Production plant, How Do You Make Composting Better?

As we all know, organic fertilizer composting process adopts the aerobic fermentation method. Thus, to make the compost better, you need consider many factors to meet the aerobic fermentation conditions. So what factors will influence the aerobic fermentation process in the organic fertilizer production? There are six factors you need to consider in the organic fertilizer fermentation process.

According to the mentioned above, you can buy the organic fertilizer composting turner and the solid-liquid separator for your $60,000 organic fertilizer production line. By using the two machines, you can solve six problems mentioned above. And you make better compost for the $60,000 organic fertilizer production plant.

What Composting Machine Can You Buy For The $ 60,000 Organic Fertilizer Production Plant?

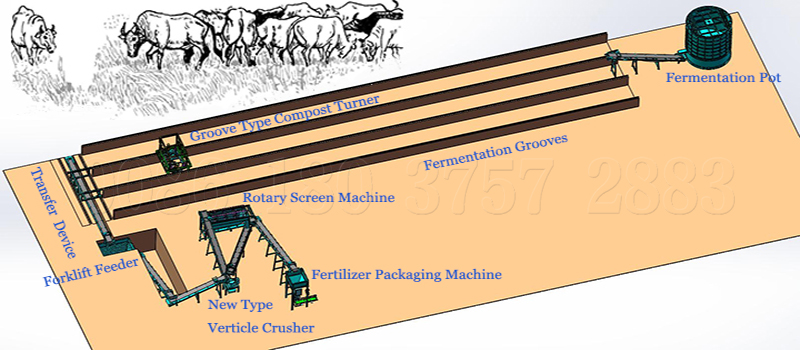

As mentioned above, you need the composting machine to adjust the temperature, the moisture and the oxygen amount when composting the organic fertilizer. So what organic fertilizer composting machine you can buy with the budget of $60,000? There are different sizes and configurations of the composting turner machines in SX organic fertilizer equipment production base. According to your budget, we suggest that you choose one between the self-propelled windrow compost turner and the groove type compost turner.

The SX organic fertilizer groove type composting machine is suitable for composting in the groove. And when you adopt the windrow composting system, you need use the self propelled compost turner. You can select them according to your factory construction.

The detailed technical specifications about these two composting machine are as following.

The Working Capacity

The material depth that the SX groove type compost turner can turn ranges from 0.8 m to 3 m. And the machine can flip the organic waste with width of 2 m-20 m .For the $60,000 organic fertilizer production line, the SXCF-3000 groove type composting machine is enough for you.

The Flipping Device

We adopt the steel plate with thickness of 12 mm. By equipped with this kind of the flip device, you can make the compost more effective. And when the machine is working, you can flip the organic manure in all directions. Furthermore, you can be easy to replace the broken flip teeth.

The Compost Capability

While flipping the organic manure, the SX self-propelled windrow composting machine can move forward 8m per hour. The compost turner can disposal 400㎥-500㎥ organic manure in an hour.

The Flipping Device

While designing the organic manure moving compost turning machine, we install a flipping shaft with diameter of 600mm in the machine. The flipping shaft can improve the fertilizer compost turner efficiency.

The technical parameters mentioned above are for reference only. Because our company have the customize service, you can choose the groove type compost turner size according to your $60,000 organic fertilizer plant.

How Do You Buy Crushing Machines For $60,000 Organic Fertilizer Production Plant

With the budget of $60,000, you can select the organic fertilizer crusher according to the working effective and the structure. There are many types of the organic fertilizer crushing machine with high performance in SX. But for the $60,000 organic fertilizer production lines, the new type vertical crusher is more suitable for your organic fertilizer plant. The vertical crushing machine price is reasonable. And the vertical crusher machine produced by the SX has a good crushing effect. Our technical personnel designs a reasonable structure for the vertical crushing machine. The special specifications are as following.

The technical parameters change as the type and size of the organic fertilizer vertical crushing machine. If you provide us with the special specifications about the crushing machine, we will recommend the suitable crushing machine to you. You can also select the crusher by yourself according to your $60,000 organic fertilizer production line. We will offer the fair price to you.

What Kind Of The Screening Machine Can You Choose For The $60,000 Organic Fertilizer Production Lines?

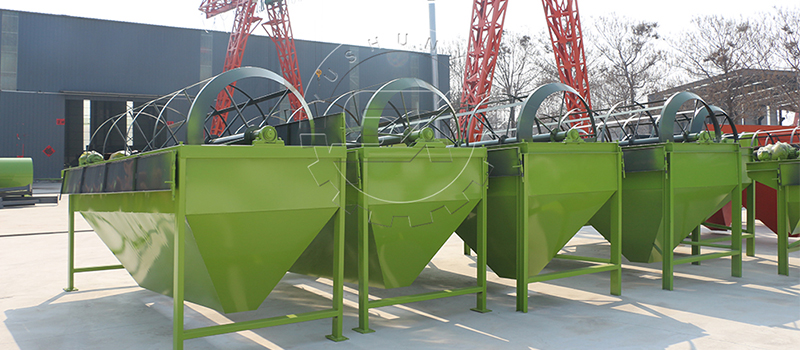

Most of the organic fertilizer use the screening machine to increase the fertilizer quality in the organic fertilizer production line. For the $60,000 organic fertilizer production line, the rotary screening machine will be the best choice for you. In SX, you can select many types of the rotary sieving machines. We make some special design about the screening machine. The details are as follows.

You can refer the above technical parameters. And according to the $60,000 organic fertilizer production line, you choose the sieving machine. Or you can propose the requirements about the screening machine to us. We have the customized service. We can customize the organic fertilizer rotary screening machine upon your requirements.

How To Make The Packaging Process Of The $60,000 Organic Production Line More Efficient?

For packing the organic fertilizer more effectively, you can use the organic fertilizer automatic packing machine to replace the manual packing. SX designs specially single bucket automatic packing scale and the double buckets automatic packing scale. But because your budget for building the organic fertilizer production plant is $60,000, we recommend that you purchase the single bucket automatic packaging machine. There are many advantages about the single bucket automatic packaging machine also have many advantages. You can know about them from the follows.

The above five aspects are the advantages of the SX automatic packing scales. However, you should note the dust-proof treatment and precision control while using the packing machine. By doing so, you can use use the packaging machine more effectively.

The seven aspects are about how to set up the $60,000 organic fertilizer production line. These are summarized based on our years of experience. Therefore, they are just for your reference. You can contact with us while starting an organic fertilizer production business. We will provide you with some reasonable suggestions about the organic manure production line.