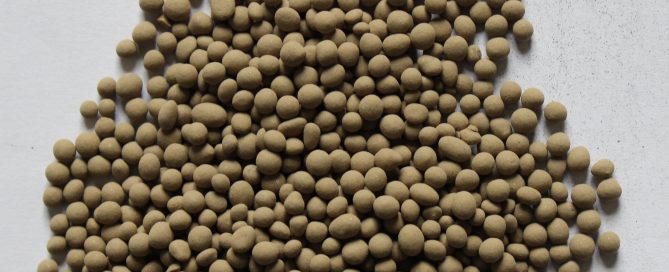

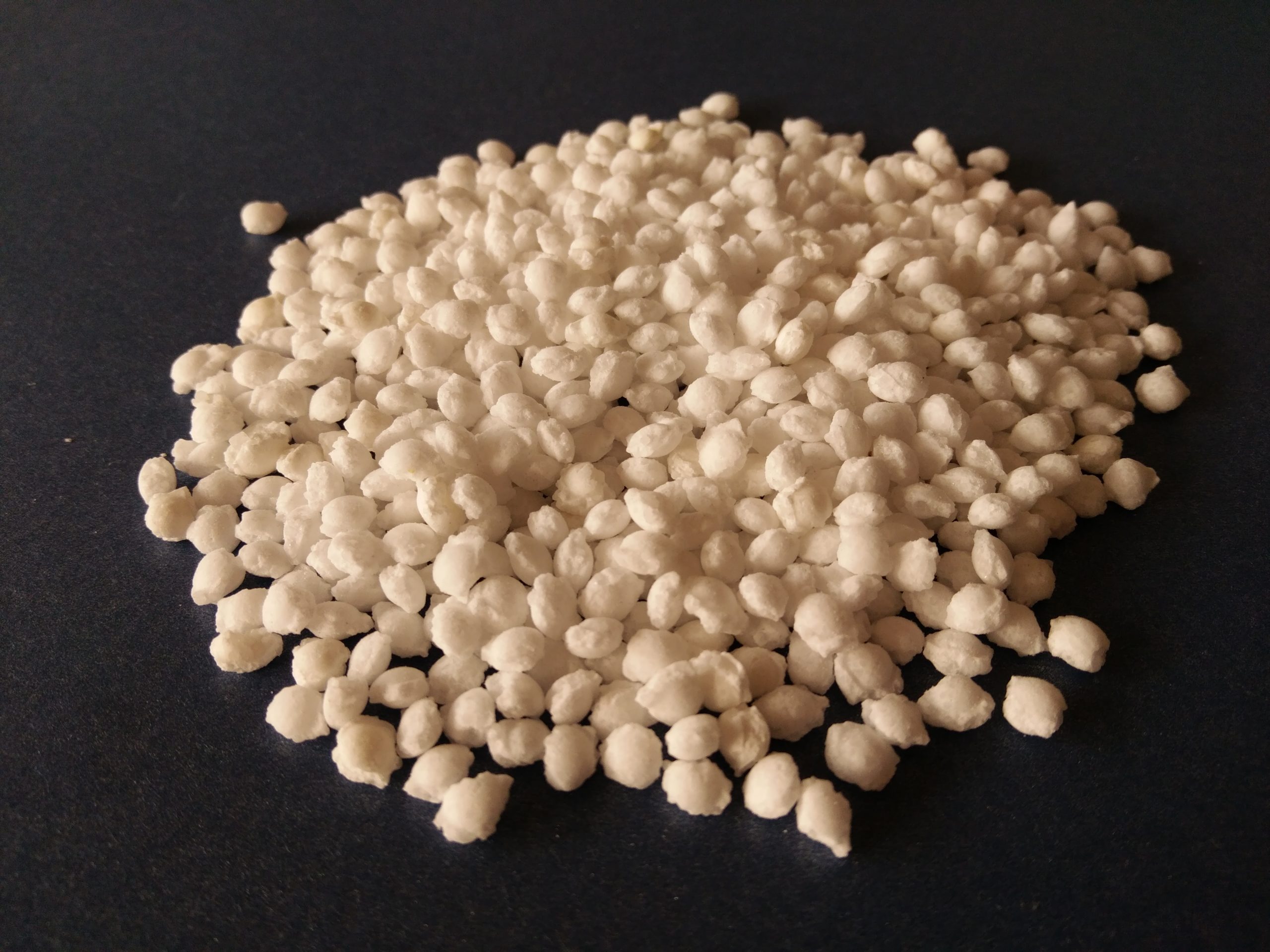

The rotary drum granulator is a kind of advanced fertilizer production equipment. More and more fertilizer producers use the rotary-drum granulator to make the fertilizer granules. But why? Mainly because there are many technical characteristics on the rotary drum granulating machine. We design the rotary drum pellet machine with many advantages such as no pollution, high economic efficiency and special design. You can know about some specific technical parameters about the machine from us. In addition, we can also give you the technical support about installing and operating the rotary drum pellet machine. We have many years of the fertilizer equipment production experience. Therefore, you can trust that we can provide you with quality granulator at fair price.

In the granular fertilizer production lines, more and more people would like to use the rotary drum granulator for granulating the fertilizer. It is mainly because of five technical characteristics on the rotary drum granulating machine. You can know about the five characteristics from the followings.

By using rotary drum granulator, you can make the granulation process more efficient. In addition, in the fertilizer production process, the machine runs safely and stably.

What Are The Advantages Of The Sx Rotary Drum Granulation Machine?

Compared to the traditional granulation machines, there are many advantages of the SX rotary drum granulator. You can learn about the advantages from the followings.

The above mentioned is for your reference only. There are also other advantages like low energy consumption on the SX rotary drum granulating machine. However, from the above, the rotary drum granulation machine produced by SX is a good choice if you want to buy one.

The Detailed Technical Specification Of The Sx Rotary Drum Granulation Machine

When buying the rotary drum granulation machine, it is important for you to know about the technical parameters. There are many types of the rotary drum granulating machine in SX. The followings are the specific technical specifications.

The Capacity

According to the granulation production lines with different production capacities, we have produced the rotary-drum granulator with different productivity. Generally speaking, you can use the SX rotary drum granulation machine to produce 1-30 tons of the fertilizer particles in an hour. Therefore, you can choose the appropriate model according to your production plan.

The Install Angle

Usually, when installing the rotary-drum pelletizer, we will set 2-5° of the inclination angle. The installation angle is to make the fertilizer particles easier to discharge. By doing so, you can get the high granulating efficiency through operating the rotary drum pellet machine.

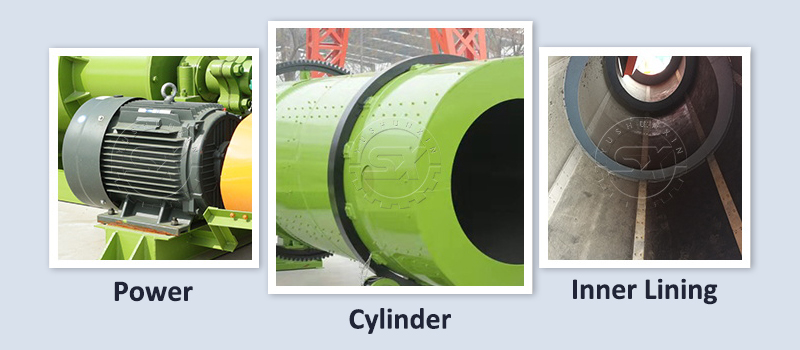

The Power

As mentioned above, our rotary drum granulating machine is an energy-saving production equipment. You will cost 5.5-37 kw of the total power by using the SX rotary drum granulation machine. Therefore, you can lower the power consumption when using our rotary-drum granulating equipment.

The Cylinder

We produce the rotary drum granulating machine cylinder with the diameter of 1200mm-3200mm and the length of 4000mm-10000mm. In general, when the cylinder with larger diameter and longer length, you will get higher output of rotary drum granulation machine. However, the cylinder rotates slower at the same time. For example, you can use the SXZGZ-2080 granulation machine with a diameter of 2000mm and a length of 8000mm to produce 8-15 tons of fertilizer granules in an hour. The rotate speed of the cylinder is 11r per minute. When you use the SXZGZ-3210 machine with a length of 10,000mm and a cylinder diameter of 3200mm, you can make 15-30 tons of the fertilizer granules per hour. However, the SXZGZ-3210 granulation machine cylinder rotates 9.5r per minute.

The above data is for your reference only. In actual production, we will improve and modify some parts according to customer needs. If you have other requirements for the structure of the rotary drum, you can put them forward and we will design the machine for you free of charge.

Here is the technical parameters about the SXZGZ-1240, SXZGZ-1560,SXZGZ-1870,SXZGZ-2080,SXZGZ-3210 rotary drum granulator. The data is just for your reference.

| Model | Power(kw) | Diameter(mm) | Length(mm) | Installation Angle | Rotary Speed(r/min) | Capacity(t/h) |

|---|---|---|---|---|---|---|

| SXZGZ-1240 | 5.5 | 1200 | 4000 | 2-5° | 17 | 1-3 |

| SXZGZ-1560 | 11 | 1500 | 6000 | 2-5° | 17.5 | 3-5 |

| SXZGZ-1870 | 15 | 1800 | 7000 | 2-5° | 11.5 | 5-8 |

| SXZGZ-2080 | 18.5 | 2000 | 8000 | 2-5° | 11 | 8-15 |

| SXZGZ-3210 | 37 | 3200 | 10000 | 2-5° | 9.5 | 15-30 |

How To Buy The Rotary Drum Granulation Machine Within The Budget?

When you intend to use the rotary drum granulation machine for granulating the materials, it is important for you to choose the right machine within the budget. Then how do you choose the suitable rotary-drum granulation machine? You can consider this question from the following three aspects.

The price changes with the specifications of the rotary drum granulation machine. For example, you can buy the SXZGZ-2080 rotary drum granulation machine with the budget of $360,000. when you manage to run the $550,000 granular fertilizer production lines, the SXZGZ-3210 rotary-drum granulation machine is more suitable.

There are different types of the rotary drum granulator with different productivity. For reducing the purchasing cost , you need to select the rotary drum granulator according to your production plan. For instance, when producing 5-8 tons of fertilizer particles per hour, you can use the SXZGZ-1870 rotary drum pellet making machine.

In addition to the above two points, there are also other factors such as the production site planning that will affect your choice of granulator. You can contact us directly about this issue. We will provide you with reasonable suggestions as soon as possible.

Where Can You Get a Best Drum Granulator at the Favorable Price?

You can buy a cost-effective drum granulator in FPC company. FPC is an established fertilizer rotary drum granulator machine supplier. We have over 15 years of fertilizer equipment production experience. Therefore, you can get the best rotary drum granulator machine from us. What’s more, you can get more since you get FPC rotary drum granulation equipment. The details are as follows.

There are also other best sevices in FPC company which you can get after buying our rotary drum fertilizer pellet machine. If you are searching for a drum type fertilizer granulator, welcome to inquiry us. We will provide you with the detailed and precise quotation.

How To Install The Rotary Drum Granulation Machine ?

The safe and stable operation of the machine is inseparable from its installation process. Therefore, it is necessary for you to know about the machine install process before buying it. There are five steps to install rotary drum granulator. You can know about the specifications from the followings.

What You Can Get After Choosing The Sx Rotary Drum Granulator?

Once you select the SX rotary drum granulation equipment, you can experience many special service. The following are about the SX special service and can be your reference.

As the old-brand fertilizer equipment producer, we have always thought of providing customers with high-quality machines and excellent service as the purpose. We believe you can get a good buying experience from SX.

The above is about the rotary drum granulator. You also get the further knowledge about the SX fertilizer rotary-drum pellets making machine through the above. we have many years experience of making the fertilizer production equipment. Therefore, you can trust we can provide you with qualified rotary drum granulator at the best price.