How to run an NPK fertilizer plant at the best cost?

When planning an NPK compound fertilizer production project, what should you consider? The most important part is the cost. Therefore, when you calculate the NPK fertilizer plant cost, what aspects should you consider? According to our years of experience, there are 6 points you need to consider. The six aspects are as follows.

The six aspects can be your reference while calculating the cost of the NPK compound fertilizer factory. You can also tell us about your NPK compound fertilizer production plan. We will give you the best plan for building the fertilizer manufacturing company.

How much will it cost when setting up an NPK powder fertilizer plant?

When building the fertilizer plant, the machine is dispensable. While producing the powder NPK fertilizer, you need to buy the machines for batching, crushing, mixing, screening and packing. The followings are about these five machines.

Batching System

For making the powder NPK fertilizer with comprehensive nutrients, you’d better follow the formula proportion strictly. Therefore, you can use the compound fertilizer batching machines at the batching process. FPC dynamic and static automatic batching machines can complete the ingredients more accurately and efficiently. Moreover, there are many types and specifications of the fertilizer batching equipment in FPC you can choose.

Crushing Machine

There are different sizes of the straight fertilizer. In order to make the nutrients distribute evenly, you’d better crush the raw materials into uniform size. What’s more, the crushed NPK fertilizer is conducive to mechanical fertilization. For crushing fertilizer materials more effectively, we recommend you use FPC new type vertical crushing machine. You can select the crushing machine based on your NPK fertilizer production budget.

Mixing Equipment

In order to make nutrients distribution evenly, you can use the fertilizer mixing machine. Because FPC mixing machine has the characteristics of low energy consumption and high working efficiency. For example, the SXSJ-0830 horizontal mixer consume 11 kw. the mixing speed can up to 35r per minute. Thus, you can lower the energy consumption and improve the mixing efficiency.

Screening Machine

By using the screening machine, you can remove the unqualified substances to increase the NPK fertilizer purity. The rotary screening machine FPC produces can sieve the solid materials with size of up to 300mm.

Packing Machine

To improve the production efficiency, you can use the automatic packing machine to accelerate the packing speed. FPC automatic packing scales can package about 250-300bags of fertilizer per hour. Moreover, it can correct the errors automatically.

The above is the fertilizer production equipment you should to deploy for the NPK powder fertilizer. You can calculate the powder NPK making equipment cost by comparing machines price from different fertilizer equipment producers.

How To Customize The Granular NPK Fertilizer Production Line At The Best Cost?

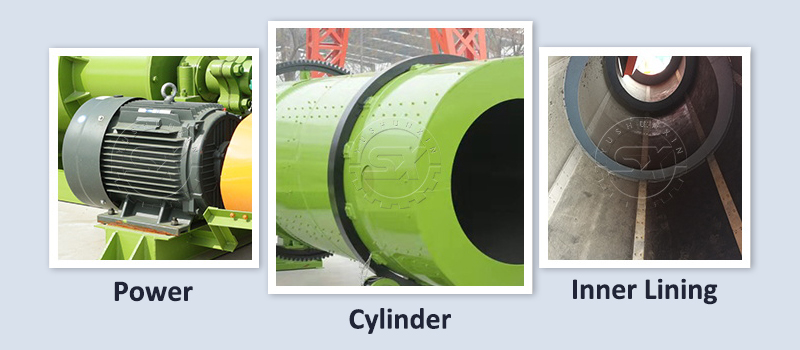

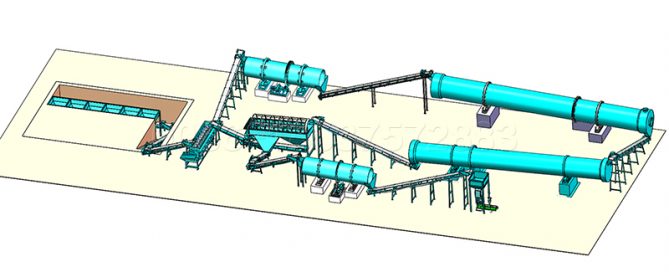

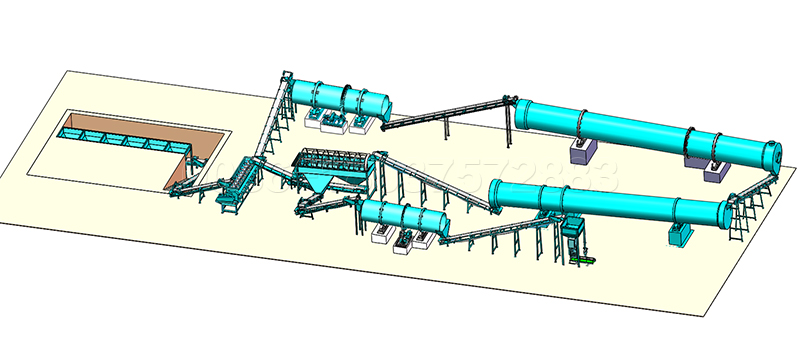

Compared with the NPK powder fertilizer plant, you need to deploy more fertilizer machines for the granular NPK fertilizer plant. Therefore, the cost of the granular NPK fertilizer factory is more than that of the powder one. The followings are the machines you need to deploy for the NPK granules production line.

As mentioned above, you need to purchase the production facilities based on your NPK fertilizer plant cost. If the budget of the NPK granular fertilizer plant is limited, you can replace the dryer and cooler with the manpower. However, you can get the high production efficiency of the granular NPK fertilizer production line after deploying these machines.

What’s The NPK Fertilizer Plant Project Cost?

When starting the NPK fertilizer plant business, you’d better consider the whole cost from three aspects. There are some aspects you need to consider. You can get the detailed information from the following.

How Do I Select The Ideal Fertilizer Equipment Manufactures?

For arranging the investment cost of the NPK fertilizer plant, you should select the fertilizer equipment makers strictly. When selecting, we suggest you consider it from three aspects. The details are as follows.

By considering the above three aspects, you can select the ideal NPK fertilizer equipment suppliers. What’s more, you will establish the NPK fertilizer production line at best cost.

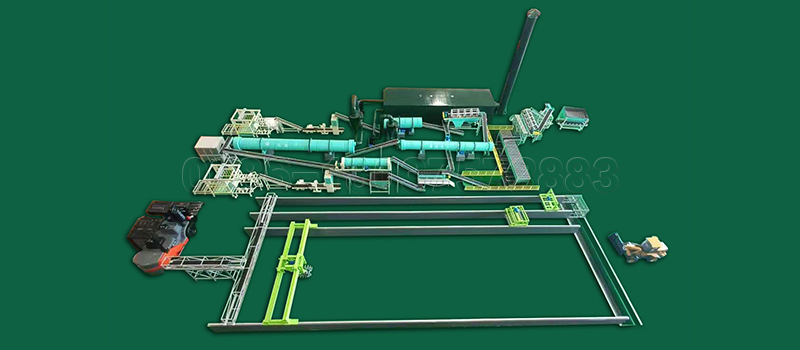

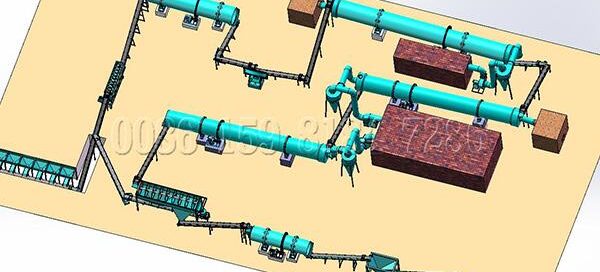

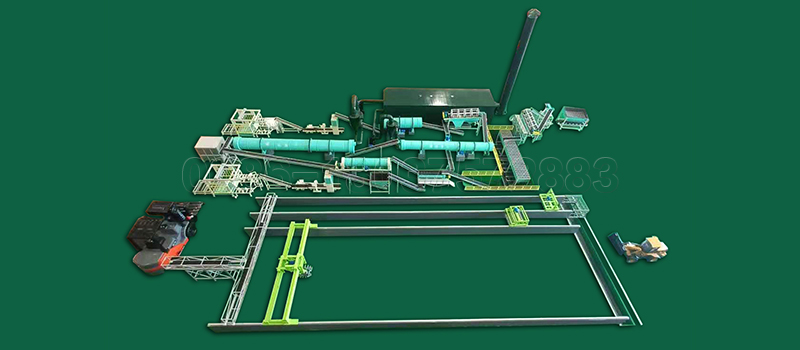

How To Design The NPK Fertilizer Plant At The Best Cost?

In order to save planning investment, shorten construction period, reduce production cost, and make full use of land resources, you can divide the factory into the following three parts according to production needs and use function

Through such a clear division of factory function zone, you can not only rationally arrange the plant area, but also make the people flow and logistics more convenient. Therefore, you can improve the working efficiency of the NPK fertilizer production plant.

How Do I Collect The Raw Materials For Making The Npk Fertilizer?

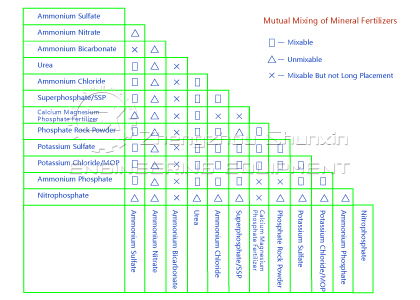

While collecting the NPK compound fertilizer raw materials, we suggest you’d better be clear about the chemical properties of the base fertilizers. In this way, you can produce the quality NPK fertilizer. Here are three tips for you.

By paying attention to the above three aspects, you can reduce materials waste. What’s more, you will produce the quality NPK compound fertilizer with qualified raw materials.

The Cost Of NPK Fertilizer Plant With Different Production Scales

The different production scales of the NPK fertilizer plant will have the different budget. According to our years of experience, we can divide the production scale into three ranges of 1-5t/h, 5-10t/h and 10-20t/h. The following content can be your references.

The 1-5t/h Production Scales

You will have a relatively low investment cost for building the NPK fertilizer plant with such production scales. For example, when producing the 5 tons NPK fertilizer pellets per hour, you just need to buy SXYZ-3600 pan granulator.

The 5-10t/h Production Scales

When making the 5-10 tons the NPK fertilizer per hour, you should build the fertilizer plant with medium scales. Thus, you should get a higher NPK fertilizer plant cost. For example, you should prepare about $100,000 to set up the 10t/h NPK fertilizer production line.

The 10-20t/h Production Scales

This is a large NPK fertilizer manufacturing factory. When initiating such NPK fertilizer making business, you should prepare the capital of over $150,000. But you will get more profit from running such fertilizer production plant.

Through the above, you will know more about calculating the plant cost of the NPK compound fertilizer for different scales. What’s more, you can contact with us while building the NPK fertilizer plant. We can provide you with the latest quota about the whole set of NPK fertilizer production line.

How To Set Up The Npk Fertilizer Plant With Different Budgets?

With different budgets, you can set up the NPK fertilizer plant with different scales. As summarized from our experience, there are three budget ranges you can refer to. The first budget range is $10,000-$30,000, the second one is $30,000-$50,000, the third one is over $50,000.

The above data is just for your reference only. You can change the fertilizer machines and production line lay out based on your real production condition. If you choose FPC, we will provide you with some reasonable suggestions.

As the old-brand compound fertilizer equipment supplier, we have sold our fertilizer machines to home and abroad. Moreover, our customers highly praise the quality of the fertilizer making machines produced by FPC. Therefore, while building the NPK fertilizer factory, you can email to us. You will get the fertilizer production equipment at the best price. You will also build the NPK fertilizer plant at best cost.

Error: Contact form not found.