The principle of NPK compound fertilizer production line is to produce the NPK compound fertilizer by mixing two or three basic fertilizers mechanically. Because NPK compound fertilizer has the characteristics of comprehensive nutrient and high nutrient content. So compound fertilizer is widely popular with fertilizer consumers. NPK compound fertilizer generally has two forms: powdery and granular. After comparing the production technology and product quality of these two fertilizers, it is found that NPK granular fertilizer has higher economic value. Therefore, many fertilizer manufacturers prefer to produce granular NPK fertilizer. For making high-quality NPK granular fertilizer, you need to consider many ways, such as the selection of raw materials, granulation process, coating process and production line design. In conclusion, as a manufacturer of fertilizer production equipment for many years, we will provide you with first-class pre-sale and after-sales service.

Granular Npk Compound Fertilizers Or Powder Ones, Which One Will Make More Benefits For You?

There are two types of NPK fertilizer in forms. One is granular NPK, and the other is powder forms. Actually, NPK fertilizer manufacturers sell more NPK granular fertilizer in the fertilizer market. But why? Let’s compare these two types of NPK compound fertilizer.

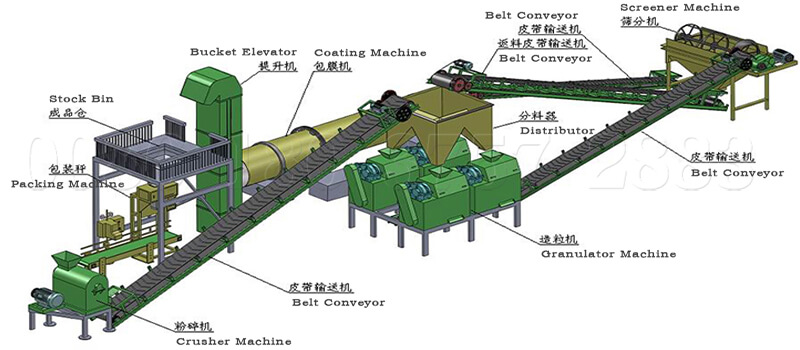

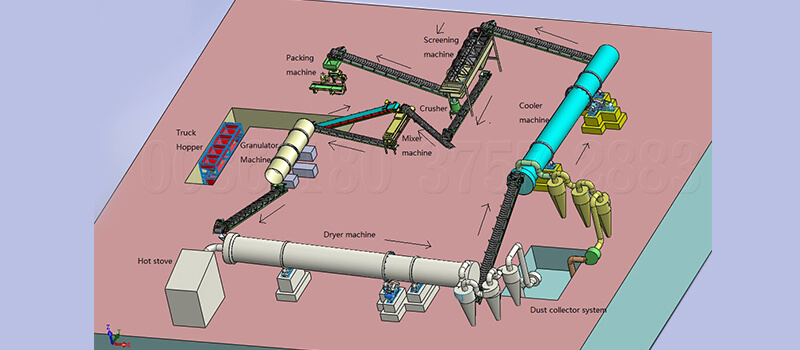

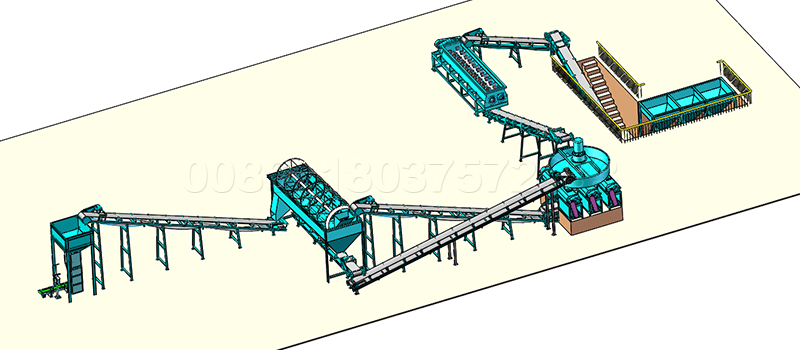

When fertilizer manufacturers produce powder NPK fertilizer, they will use a fertilizer crushing machine to crush two or three kinds of straight fertilizers. After crushing, they use the fertilizer screener to screen out the bulk fertilizer. Then the qualified powder fertilizer will be metered by precise batching machine according to the scientific calculated compound fertilizer formula. Next, fertilizer producer put these powder fertilizers into mixing machine in order to mix them evenly. At the end, uniform fertilizer can be sold out of the factory after packaging.

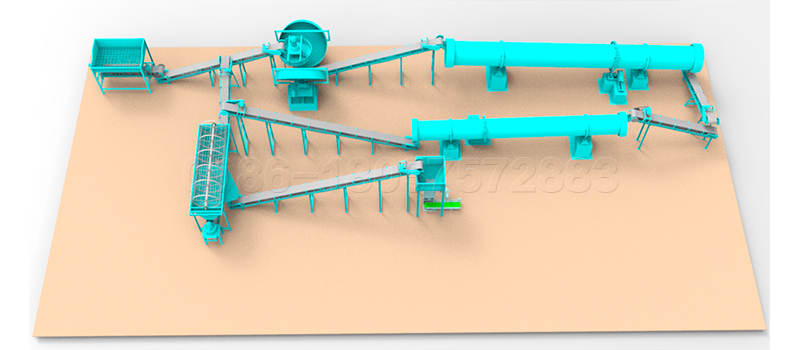

Granular fertilizer is a secondary processing on the basis of powder fertilizer production process. By using granulators, you can produce different shapes of granular fertilizer to meet the needs of the fertilizer market. After granulation, in order to meet the sales standards, you should use fertilizer dryer to remove extra After drying,there will be the fertilizer caking because of high temperature. Therefore, you need to apply the fertilizer cooler to reduce the temperature. To be clear, if you apply dry granulation, you do not need to drying and cooling these two processes. Next, to improve the nutrient utilization rate of fertilizer, makers will use compound fertilizer coating machine to coat the granular fertilizer. Finally, they pack the coated fertilizers and sell them out of the factory.

Powder fertilizer has two major defects. The first defect is that powder fertilizer is volatile. When customers use powdered fertilizer, dust will occur. The dust will cause pollution to the surrounding environment. The second is that powder fertilizer is easy to caking. Caking powder fertilizer can cause inconvenience to fertilizer application.

Compared with powdery compound fertilizer, granular compound fertilizer dissolves slowly and does not adversely affect the root of plants. Moreover, because granular fertilizer has fluidity, it can reduce the possibility of caking. Besides, the diameter of granular fertilizer is generally 1-5 mm, which can be suitable for mechanical fertilization.

Through the above production process of powder NPK compound fertilizer, it is obvious that the production process of powder NPK fertilizer is simple. You just need a few the fertilizer production mechanical equipment in powder NPK fertilizer production line. All in all, the cost of producing powdered NPK is low.

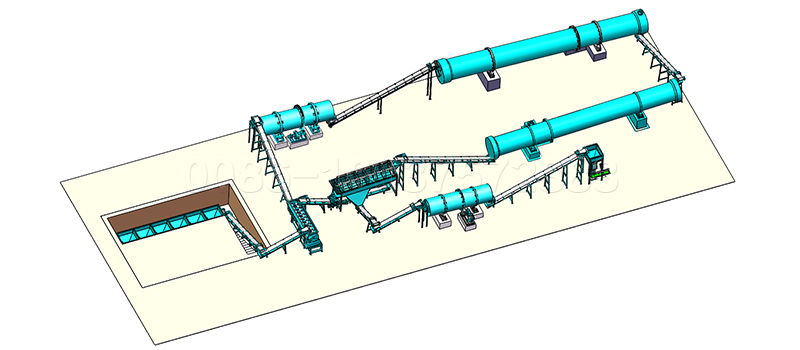

NPK granular fertilizer production process includes granulation, drying, cooling and so on, so the composition of NPK production line is more complicated. Hence you need a variety of fertilizer production equipment to assemble the NPK Granular Fertilizer Production Line . The cost you need to invest will also be high.

After comparing the above three aspects, both types of NPK fertilizers have their own advantages and disadvantages. But NPK granular fertilizer can bring more benefits to fertilizer manufacturers. So, we more recommend you to produce granule NPK compound fertilizer.

NPK Compound Fertilizer Pan or Rotary Drum Granulation Production Line You Can Choose

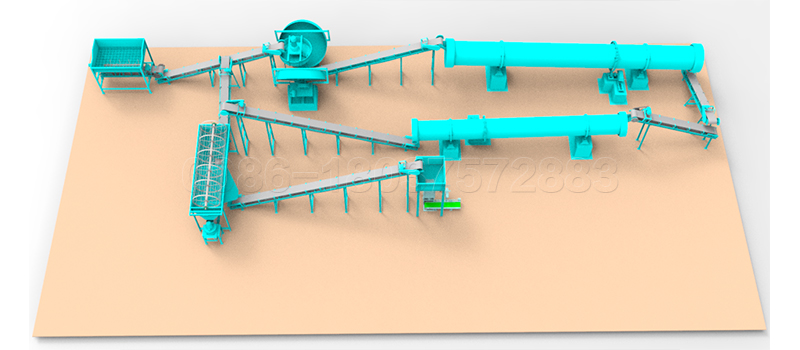

From the above mentioned, NPK granular fertilizer more meet the needs of the fertilizer market. How many kinds of NPK granulation process are there? And what is the process of granulation? There are two granulating processes in the NPK compound fertilizer production line. They are pan granulation production line and rotary drum granulating producing process.

Both granulation processes above mentioned are widely used for NPK compound fertilizer production line. In actual production, you can choose the appropriate granulation process according to your practical production capacity.

3 Reasons to Use Coating Machine While Making Npk Compound Fertilizer

During the actual production of NPK fertilizer, many fertilizer producers will use a coating machine to cover fertilizer particles in the NPK compound fertilizer production line. Mainly because after coating, NPK compound fertilizer has an obvious advantage. Let’s know about it.

First

After coating, you can increase the utilization rate of NPK fertilizer. A large number of experimental data shows that the coated NPK fertilizer has a slow-release effect. It can also reduce the loss of fertilizer gas and leaching. Therefore, you can improve the utilization rate of fertilizer through the filming process.

Second

When using the rotary fertilizer coating machine, it can save labor force. Because of the high utilization rate of coated NPK compound fertilizer, fertilization times can be reduced. At the same time, the nutrients in coated NPK compound fertilizer can meet the planted crops needs in the whole growing season.

Third

It can improve the crop qualities. The quality of crops and pests and diseases of crops are related to the amount of nitrogen fertilizer. The coated fertilizer can reduce the loss rate of nitrogen fertilizer. While ensuring that crops do not absorb excessive nitrogen, they can also transplant pests and improve quality.

To sum up, coating fertilizer can effectively improve the quality of fertilizer. Furthermore, the coated NPK fertilizer is more popular with customers. In order to make the NPK compound fertilizer more competitive , why not use the coating machine to gain more benefit.

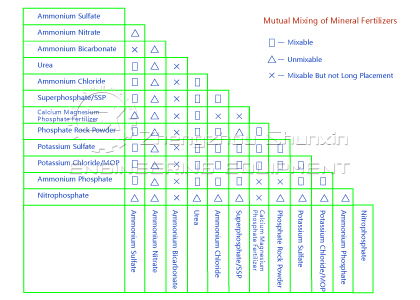

Three Raw Materials Selection Principles For Producing Npk Fertilizers You Need To Know

Selection of raw materials has a particularly important impact on the NPK compound fertilizer production line. The raw material will directly affect the quality of the final finished NPK compound fertilizer. Therefore, when you choose the raw material, you should pay special attention to the suitability of base fertilizers mixing before producing NPK fertilizer. You can consider this from these three following three aspects.

In addition, when choosing raw materials to design the formula for NPK compound fertilizer production, you still need to examine the nutrient situation of the local soil, the nutrient demand of the main plants planted in the local area, and the technical requirements of the current NPK fertilizer application.

Why do Many People Set Up NPK Compound Fertilizer Production Line

Nowadays, the proportion of NPK fertilizer in domestic and foreign fertilizer markets is increasing, and the varieties of NPK fertilizer are also increasing. So there’s a problem is that why more and more fertilizer manufacturers choose to produce NPK compound fertilizer. There are two main reasons:

The reason why NPK compound fertilizer is sold more and is popular among farmers is that the above-mentioned advantages about NPK compound fertilizer. You can produce different kinds of compound fertilizer according to different formula. The NPK fertilizer can meet the nutrient demand of different land and different crops. NPK compound fertilizer users can choose suitable compound fertilizer according to their actual needs. Therefore, NPK compound fertilizer has a great competitiveness in the compound fertilizer selling market.

From the above, NPK compound fertilizer has a lot of advantages. The NPK fertilizer is in line with the needs of the market and consumers. As a result, more and more fertilizer plants will set up NPK fertilizer production lines to produce the NPK granular fertilizer in order to make more benefit for the company.

3 Factors You Should Consider To Run Npk Compound Fertilizer Production Line

After a certain understanding of the NPK compound fertilizer production process, there is a problem you will consider. It is that how to establish the most suitable NPK compound fertilizer production line. we suggest you can consider from three sides of the production line scale, type and configuration.

If you don’t have a fertilizer production plant,you can determine the scale of NPK fertilizer production at first. After determining the the dimensions of the NPK compound fertilizer production line, you can design the fertilizer production plant according to height,length and with of the NPK fertilizer production lines.

To determine the type of fertilizer production line is to determine the type of fertilizer produced. Determining the type of fertilizer is related to the choice of fertilizer production equipment. This is also closely related to the fertilizer production costs you need to invest. Therefore, it is crucial to determine the type of fertilizer production line.

The production line configuration determines the production capacity of the production line. Because different production line configurations will be consisted by different types of production equipment. Each model of equipment will have a specific production capacity. Determine your annual production capacity can determine what type of production equipment you need to configure.

As long as you can identify these three problems, you will soon be able to establish the most perfect NPK compound fertilizer production line. Of course, you can also consult us. We will make reasonable suggestions for you according to the relevant contents you provide.

Error: Contact form not found.