Chicken manure is one of important raw materials ro make the organic fertilizer. As the same time, you can also make liquid fertilizer from chicken manure. Then how to make liquid fertilizer from chicken manure? You can get the detailed production process of liquid chicken manure fertilizer from the following. What’s more, you can know that complete production equipment for chicken manure liquid fertilizer. When disposing the chicken manure, FPC chicken manure liquid fertilizer complete production line will be your best choice. We have many years of experience in organic fertilizer production line design and production. You can get entire liquid chicken manure fertilizer production line at the best cost in FPC company. Welcome to email us for consulation.

Why Is The Chicken Manure Suitable For Making Liquid Manure?

The feed nutrients cannot be absorbed entirely in the shorter digestive tract of the chicken and then excreted with the feces. Therefore, the large amount of nutrients remain in chicken manure. You can recycle these nutrients for making the quality liquid fertiliser. The following will give you some useful information.

The chicken manure nutrients are related to its growth stage and economic use.

From the above, you can know the reason why the fertilizer producers use the chicken manure as the raw materials of the liquid fertilizer production. When running the chicken manure liquid fertilizer production line, you can consult us about the raw materials selection. We can give you some advice about it.

How Do You Separate The Wastewater From The Chicken Manure To Make The Liquid Fertilizer?

After collecting the chicken manure, then how do you process it to make the liquid fertilizer? There are two steps in the initial treatment of chicken manure. One is to crush the chicken manure, the other is to dewater the chicken poop. The followings are the details about these two steps.

Crush The Chicken Manure

When you collect the chicken waste, there must be some bulk materials in it. In order to speed up the solid-liquid separation, you need to use the fertilizer crushing machine to grind the chicken manure. There is a new type vertical crushing machine in SX you can choose. You can use the SX vertical crusher to process up to 15 tons of the chicken manure per hour. Moreover, it has the advantages of high working efficiency and long service life.

Separate Solid And Liquid

There are approximately 50% water content in the fresh chicken manure. You should use the solid-liquid separator to get the wastewater from the chicken manure. The chicken wastewater also contains the large amount of the nutrients. You can use the waste water from the chicken manure to make the liquid fertilizer. While separating the chicken dung solid and water, we recommend the chicken manure dewatering machine produced by SX.

After the chicken manure solid-liquid separation, you can not only produce the liquid fertilizer with the waste water, but also produce the organic fertilizer with the solid chicken manure. By doing so, you can make full use of the raw materials to maximum the benefits.

Before Making The Liquid Fertilizer, How Do You Process The Chicken Manure Wastewater?

Follow the above operation, you can get the waste water which is the raw materials of making liquid fertilizer from the chicken manure. Then how do you treat the waste water to make the liquid water soluble fertilizer? The following is the treatment of the chicken manure waste water.

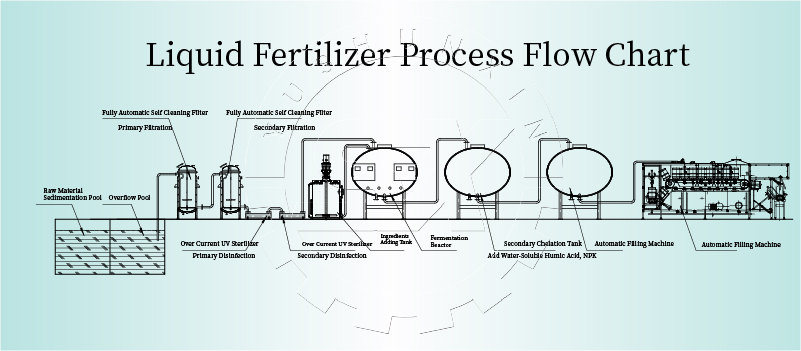

There are some impurity substances like stones and plastic in the chicken poop waste water. Therefore, you need to build the sedimentation tank for it based on the amount of the raw materials. By doing so, you can improve the raw materials purity for making the liquid fertilizer.

Besides the sediment tank,you should set up an overflow tank next to the sedimentation tank. In this way, you can discharge the waste water after sedimentation to make the room for unprocessed raw materials. You can also improve the efficiency of liquid manure production.

After doing the above, you can improve the purity of the chicken dung waste water. However, you still continue to improve the purity of the materials for manufacturing qualified liquid manure products. Next, you can pump the original liquid in the overflow tank through the centrifugal pump to the pipeline for the next liquid fertilizer production process.

How To Improve The Raw Materials Quality For Making The Chicken Manure Liquid Fertilizer?

After the sedimentation, there are still tiny foreign particles, parasites and infectious bacteria in the chicken waste liquid. What you should do next is to remove these substances. But how? The following can be your reference.

You can improve physical and chemical properties of the raw materials for the liquid fertilizer production through filtering and sterilizing. You can also produce the high-purity liquid fertilizer with such raw materials.

Filter Twice

Because the liquid fertilizer purity is determined by the raw materials purity. There, you need to use the liquid filter to remove the impurity substances in the liquid. For improving the filtering efficiency, SX designs the liquid fertilizer filter specially. When designing the liquid manure production line, we set up two filters to ensure the original liquid purity. In addition, we use the stainless steel to produce the filtering machine to prevent the raw materials corrosion. Therefore, you can use the SX liquid filtering machine for 10 years at least.

Sterilize Twice

There are some harmful bacteria like the parasites and infectious bacteria in the chicken manure. For preventing the infectious bacteria into the ecosystem to threaten the human healthy and plant growth, you need to eliminate them completely. SX has designed the liquid UV sterilization equipment to solve this problem. The SX UV sterilization machine have sterilization rate of up to 99%. During the production, the chicken manure will be sterilized twice. In this way, you can make sure the materials quality.

What other materials should you add for making chicken manure liquid fertilizer?

Under the action of the centrifugal pump, you can fill the treated chicken waste water into the ingredients tank. Then you should put some auxiliary materials into the tank for the next fermenting process. You can know the specific information from the follows.

What you need to note is that you should crush the bulk materials before adding these substances into the tank. By doing so, you can speed up the dissolve rate of the auxiliary materials to mix them evenly.

How to ferment the chicken manure liquid fertilizer?

There are three aspects you should note when fermenting the materials for making the chicken manure liquid water soluble fertilizer. They are fermented temperature, environment and time. You can learn more information from the followings.

Fermented Environment

While producing the liquid water soluble fertilizer, you should choose the anaerobic fermentation system. Therefore, you should ensure that the liquid is fermented in the completely enclosed environment. By doing so, the chicken waste liquid will contact with air to affect the fermentation effect.

Fermented Temperature

In order to make the anaerobic bacteria more active, you should keep the fermented temperature at 28℃-35℃. You can make the fast fermentation at this temperature range.

Fermented Time

You will spend about 72h on the chicken waste water fermentation. After 72 hours, you can get the high-quality liquid fertilizer which is thoroughly fermented.

Regarding the fermentation process, we have designed the liquid fertilizer ingredients tank and fermented tank. You can tell us your liquid fertilizer production plan. We will design a liquid fertilizer production line for you for free.

The above is about the liquid chicken manure manufacturing process. The information is for you reference only. You can contact with us for the further detailed information about making the liquid fertilizer from the chicken manure.

What Is the Cost of Complete Chicken Manure Liquid Fertilizer Making Line?

The cost of liquid chicken manure fertilizer production is related to many aspects, such as machinery cost, maintenance cost and operation cost. Therefore, it is hard to get a precise cost for running a chicken manure liquid fertilizer. However, you can cut the unnecessary cost lost through finding a certificated and capable liquid fertilizer machine manufacturer.

FPC liquid fertilizer production machine is made of quality materials—stainless steel. The materials can avoid the raw materials corrosion efficiently. What’s more, the whole line can be used at least 10years. Thus, you can save the post-maintenance costs. In addition, you can save operating cost by using our liquid fertilizer machines. All of them takes energy-saving design. For example, the self-priming pump power is 0.75kw/h in the 500 tons per year chicken manure liquid fertilizer production line.

We have own fertilizer machinery production factory. All the machines are sold by our factory directly. Therefore,you can get the whole chicken manure liquid fertilizer processing line at the fair price from FPC company. Through the above, you can run a liquid chicken manure fertilizer at the perfect cost.

You can email and tell us your requirements. We can calculate the basic cost of liquid fertilizer production line according to your needs. Meanwhile, our technical staff will give you professional advice. Welcome to our website for free inquiry.