Because liquid fertilizer has the advantages of wide sources of raw materials, high economic value and simple production process, more and more fertilizer factories have begun to produce liquid water-soluble fertilizer. As a manufacturer engaged in the fertilizer equipment production for many years, we have designed the whole liquid fertilizer production line. While you intend to produce the liquid fertilizer, SX will be your relatively better choice. There are advantages of the SX liquid fertilizer production line such as simple operation and short production period. We can also offer you some useful advice about the material selection and treatment. You will also know more detailed information about the liquid fertilizer production from us.

The machines used in liquid fertilizer production line

High-moist materials shredder, solid-liquid separator, filter device, UV sterilization, mixing system and fermentation system.Liquid fertilizer production line

The liquid fertilizer purity depends on the raw materials purity. Therefore, it is important to process the raw materials before making the liquid fertilizer. You treat the raw organic materials according to the following.

Crush The Raw Materials

In order to speed up the solid-liquid separation, you need to use a crushing machine to crush bulk materials. There are different types of crushing machines produced by SX. We can recommend suitable shredders according to your raw material type.

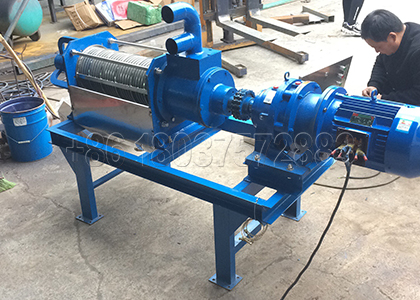

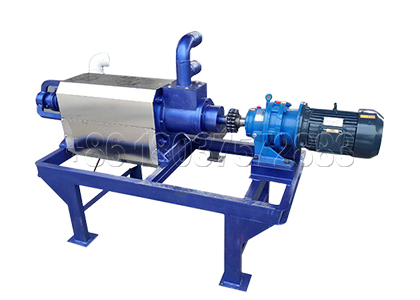

Solid-Liquid Separation

Because what you produce is liquid fertilizer, you should collect wastewater from animal waste and agricultural waste. At this time, you need to use a solid-liquid separator. The SX screw extruding solid-liquid separator can dewater materials with a water content of about 80% to about 40%.

Filter The Raw Materials

After precipitation, in order to obtain higher-purity materials, you also need to use a filter to filter the precipitated stock solution twice.

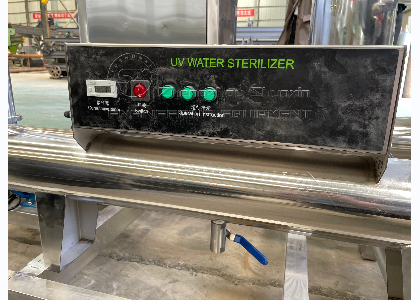

Sterilization The Materials

Because the raw materials contain harmful bacteria. In order to prevent these harmful bacteria from entering the biological chain and endangering human health and plant growth, you need to sterilize the raw materials. The UV sterilization method used in the liquid fertilizer production line designed by SX. In this way, harmful bacteria in the raw materials can be completely removed.

Through following the above five steps to process the liquid fertilizer materials, you could increase the security of the finished liquid manure. What’s more, you can get the high-purity liquid water soluble fertilizer.

After Processing The Raw Materials, What Should I Do Next For Making The Liquid Fertilizer?

There are two steps you need to do next after processing the raw materials. One is to mix the materials evenly, the other is to ferment the mixed materials. You can know about the two steps from the following.

For mixing liquid fertilizer ingredients and fermenting processes, SX has designed such batching tanks and fermentation tanks. They are composed of three layers of inner tank, heat conduction layer and heat preservation layer, which can effectively ensure that the liquid fertilizer is fermented at room temperature.

What Materials Can You Use For The Liquid Fertilizer Production?

As mentioned above, you can know that it is easy to collect the raw materials. Then what kinds of the raw materials can you collect? There are three raw materials sources you can choose. The following will provide you some useful information.

Animal Waste

There are a large number of nutrients such as protein and organic matter in the animal feces. The animal waste is one of the most important raw materials for production the liquid fertilizer. By using the animals manure, you can make the liquid fertilizer with high nutrients content.

Agricultural Waste

There are still a lot of nutrients remaining in abandoned crops. You can turn agricultural waste into treasure by making water-soluble fertilizer. The crude protein and crude fat in the agricultural can be used to promote plant growth.

Biogas Slurry

The biogas slurry is rich in nutrients. It not only contains organic matter, but also humic acid that can improve plant resistance. Therefore, biogas slurry is another important raw material for making liquid fertilizer. In addition, after being fermented under anaerobic conditions, there are still intact the nutrient content which remains in the biogas slurry.

You can get the high-quality liquid fertilizer by treating the raw materials described above. However, you need to add other substances in the raw materials to supply the liquid fertilizer you produce. By doing so, you can improve your liquid fertilizer competitiveness to make more benefits.

Why Does Many People Produce The Liquid Fertilizer?

In the fertilizer manufacturing industry, why are more and more people producing liquid fertilizer? there are three reasons for that: easy to collect the raw materials, high economic value and simple production process. The following are the detailed information about these three aspects.

Although you will have a high investment for purchasing the liquid fertilizer production equipment, you can get high profits from making the liquid fertilizer in a short period of time. Therefore, many fertilizer manufacturers have begun to produce liquid fertilizers.

What Are The Advantages Of The Sx Liquid Fertilizer Production Line?

For producing the liquid fertilizer, SX designs the production line specially. Therefore, there are many advantages of SX liquid fertilizer production line. You can know more about the production line from the following.

Because of these significant advantages, the SX liquid fertilizer production line is more competitive. What’s more, you can make the liquid water soluble fertilizer with relatively economic cost and high efficiency.

What Service Can You Experience After Choosing The Sx?

Once choosing SX, we will provide you with customized service, formula designing service and technical support. You can know more from the following.

From the above, you can know that SX has a series of perfect service system. Therefore, you can get a wonderful purchasing experience from the SX. And you will get a whole set of high-efficiency liquid fertilizer production line.

As the old-brand fertilizer production equipment supplier, we have the confidence to provide you with high working-efficiency liquid fertilizer production equipment and the first-class service. While setting up the liquid water-soluble fertilizer production business, you can contact with us. We will propose the suitable plan of manufacturing liquid fertilizer to you.