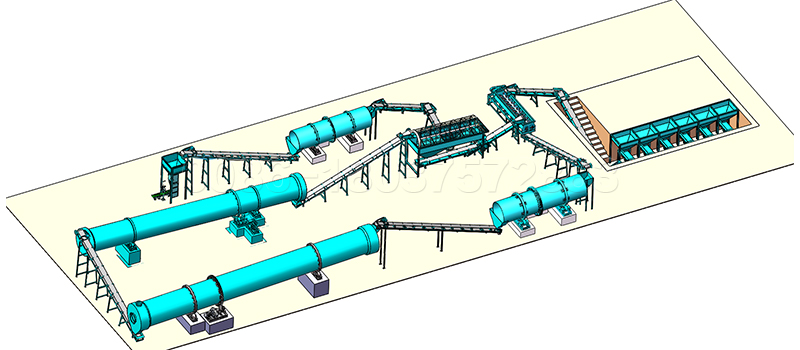

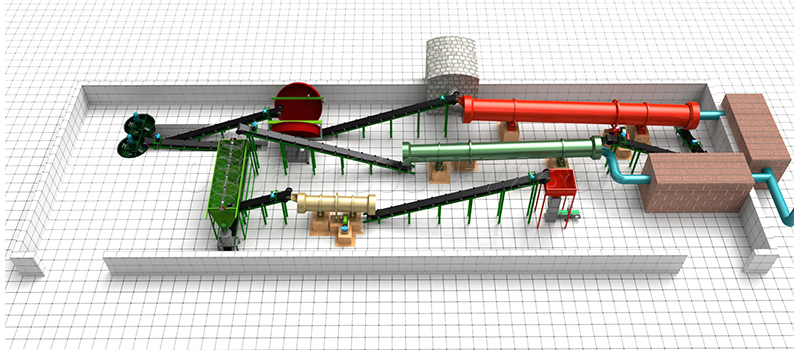

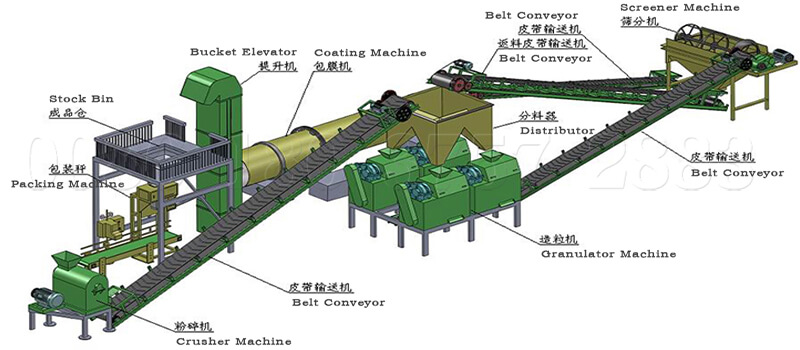

With the budget of $ 190,000, you can start the organic fertilizer making company for producing the powder or granular organic fertilizer. However, for getting the higher benefits, we recommend you make granular organic fertilizer. Because there are high demands for the granular organic fertilizer in the fertilizer market. Then how to produce granular organic fertilizer? We can divide the organic grain production process line into three stages: the preparation stage, granulation stage and after granulation While producing the organic fertilizer, you can use the production equipment to improve the efficiency of the production lines. When buying the fertilizer production machines, you can get some constructive advice from us. The followings are the specific explanation about the granular organic fertilizer production line. When running the $190,000 organic fertilizer production lines, you can get more useful information from the following.

For Granulation, What Should You Do To Start The $190,000 Organic Fertilizer Making Company?

For making the granulation process more efficient, you need to process the material before granulating. So how do you process the materials for the granulating process? The following can be your reference.

The above are preparations for granulating. What’s more, these steps are indispensable. As mentioned above, you can use the organic fertilizer production equipment to improve the working efficiency. While running the $190,000 organic fertilizer production line, you can ask us for the right type of these fertilizer production equipment.

While Granulating, What Type Of Granulator Can I Purchase To Start Organic Fertilizer Making Company?

To start the $190,000 organic fertilizer making company, there are many types of the organic fertilizer granulation machine you can use. Therefore, you can refer to the followings while selecting the fertilizer pellets making machines for your fertilizer factory.

The Churning Granulation Machine

The churning granulation machine is a new type organic fertilizer granulation machine. While granulation, the churning pellets making machine make the powder organic fertilizer form into balls under the action of mechanical agitation force and aerodynamic force. Therefore, the organic fertilizer particles produced by the churning granulation machine are harder and more beautiful. SXJZ-1200 churning granulator is suit for the capacity of $190,000 organic fertilizer production line.

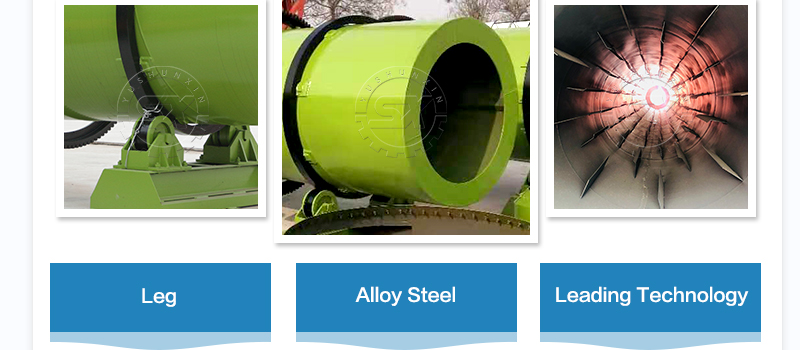

Rotary Drum Granulation Machine

There is a wide range of granulation capacity about the rotary drum granulation machine. Generally, the rotary drum pellet making machine can granulate 1-30 tons of organic fertilizer per hour. Therefore, the large scale organic fertilizer production factories prefer to deploy the rotary drum granulation machine for the granular fertilizer production line. For improving the powder organic fertilizer utilization, we set a rubber liner in the rotary drum. The rubber liner also can protect the machine from the corrosive.

Rotary Drum Churning Granulator

The rotary drum churning granulation machine is a newly developed fertilizer pellet making machine. It can make the powder organic fertilizer into specific shape. The granulation method of the rotary drum and churning granulator combines two granulation methods: rotating granulation and gear stirring granulation. Therefore, when you use it for granulation, you will get a higher ball formation rate. At the same time, this kind of the granulation machine is an energy-saving machine. Its total power is about 60kw.

Disc Pellets Making Machine

SX pan pelletizer ball rate is more than 93%. while producing the disc-type granulator, we use the radiant steel plate as materials of the base. Therefore, when working, it can operate more stably. While making the organic fertilizer granules, the fertilizer manufacturers will use a combination of a disc granulator and a rotary drum granulator. The fertilizer granules produced in this way have a smoother appearance. For the $190,000 organic fertilizer production line, we recommend the SXYZ-3600 disc granulator.

The above is for your reference only. There are different specifications of the granulation machines in SX. You can provide us with your organic fertilizer production project. We will recommend the suitable fertilizer pellets making machine for you. You can also select the ideal granulation machine to start organic fertilizer making company.

After Granulating, What Should You Do To Start Organic Fertilizer Making Company ?

After finishing the granulating process, there are still excess water content in the organic fertilizer granules. Moreover, the organic fertilizer strength is not too strong to meet the requirements of storing and transporting. Then what should you do to improve the strength of the particles? You can do the following.

As mentioned above, you can use the cooling machine and drying machine to improve the working efficiency. While running the $190,000 organic fertilizer production lines, you can make about the 5 tons of granular organic fertilizer in an hour. Thus, the SXHG-1212 and the SXLQ-1515 rotary drum cooler and drier are suitable for your organic fertilizer production lines. Of course, we can customize the drying and cooling machine upon your actual needs.

4 Advantages Of Deploying The Organic Fertilizer Coating Machine To Start Manure Making Company

There is a very important steps for producing the granular organic fertilizer. It is to coat the organic fertilizer granules. But why? What are the advantages of the coating? You can get the answer from the following.

Advantage 1

After coating, the nutrients in the organic fertilizer particles can not be lost during the storing process and the transportation.

Advantage 2

The organic fertilizer which is coated will have the characteristics of releasing nutrient slowly and being decomposed in the soil.

Advantage 3

The coated organic fertilizer is good for the farmers to fertilize mechanically. By doing so,you can ensure the fertilization efficiency.

Advantage 4

After coating, there will not be caking and nutrients loss of the fertilizer pellets during the long-time storing and transportation process.

While coating the organic fertilizer particles, you can use the coating machine produced by SX. By using the SX rotary coating machine, you can produce the coated organic fertilizer with high utilization and quality.

In The End, The Best Packing Machine To Start Organic Fertilizer Making Company .

In order to make the organic fertilizer packaging process more efficient, you can use the automatic packaging scale. With the budget of $190,000, we recommend that you buy single bucket or double buckets organic fertilizer automatic packaging machine. There are many models of the automatic packing machines in SX you can select. Our packing scales have the following advantages.

As mentioned above, these data are for your reference only. You can consult us and we will give you reasonable advice based on your $190,000 organic fertilizer production lines.

How To Buy The Right Production Equipment To Start $190,000 Organic Fertilizer Making Company ?

In the organic fertilizer equipment production industry, there are many kinds of organic fertilizer production equipment. So how to choose the right organic fertilizer production equipment is what you have to consider. You can follow the following aspects.

Following the above three aspects, you can meet the excellent fertilizer equipment producers. You can also buy the high-quality organic fertilizer production machines from them. As the fertilizer equipment manufacturers with years of experience, we can also provide you with high-performance equipment.