Because the water-soluble fertilizers have the high economic value, many fertilizer making plants have begun producing it to make more benefits. To earn more profits from the fertilizer production, you can also make fertilizer which is easy to dissolve in water. But how? The materials selection is the first step you should consider. There is a wide range of the raw materials sources. Therefore, it is easy to collect the raw materials for the water-soluble fertilizers production. Then you need to know that how to treat the raw materials before production. The processing methods are different for different raw materials. You can learn more from the below. Next, you should choose what kind of the water soluble fertilizer to make. The liquid or solid water soluble fertilizer is suitable for producing. Through the below, You will get more detailed information about it.

For producing different types of water-soluble fertilizers, you need to use the different raw materials. From the following, you can understand the raw materials needed to produce organic water-soluble fertilizer and NPK water-soluble fertilizers.

Make Organic Water Soluble Fertilizer

When making organic water-soluble fertilizer, you can collect organic waste like cow manure, green manure and crop stalks. Then you can use the organic fertilizer solid-liquid separating equipment to get the waste water from the organic manure. The organic liquid separation material can undergo certain treatment to produce liquid water soluble fertilizer. You can use the organic manure solid residue to produce organic fertilizer. By doing so, you can maximize the utilization of organic waste to make more benefit.

Make NPK Water Soluble Fertilizer

For producing NPK water-soluble fertilizers, you should collect rich nitrogen, phosphorus and potassium ingredients needed for plant growth. While selecting nitrogenous raw materials, you can use urea, ammonium nitrate and ammonium sulfate. As for phosphorus-containing raw materials, you can choose monoammonium phosphate, diammonium phosphate, etc. as raw materials to makeNPK water-soluble fertilizer. The raw materials rich in potassium are potassium chloride and potassium nitrate.

In addition to the most basic raw materials, you also need to add some functional auxiliary materials such as trace element fertilizers and synergists to supply the nutrients of water-soluble fertilizers. In this way, you will make the water soluble fertilizer with sufficient nutrients.

How To Process The Raw Material For Making The Water Soluble Fertilizer?

How to process raw materials depends on the physical form of the raw materials. We can divide raw materials into solid and liquid forms. The following are the treatment methods of raw materials with different forms for making the water-soluble fertilizers.

Liquid Raw Material

You select to collect the liquid raw materials like animal urine to make water soluble fertilizers. There are many foreign substances and the harmful bacteria in the animal manures. Therefore, you’d better precipitate, filter and sterilize them carefully. In this way, you can get high-quality organic fertilizer raw materials. What’s more, you also use the liquid raw materials treated in this way to produce high-quality liquid water-soluble fertilizers.Solid Raw Material

Regarding solid raw materials, you need to pulverize it thoroughly in advance. What’s more, you should crush the raw materials into almost same fineness. By doing so, you can speed up the dissolution of raw materials when producing liquid water-soluble fertilizers. In the production of powder water-soluble fertilizers, various basic fertilizers will not be stratified due to different particle sizes, resulting in poor use of water-soluble fertilizers.The above provides you with the treatments of two different raw materials. While making the water soluble, you can also contact with us for the detailed information. Maybe you have various raw materials to make the water-soluble fertilizer. We will propose the detailed production plan according to your raw materials.

What Kind Of The Water Soluble Fertilizer Can You Make?

In the water-soluble fertilizer sales market, there are many types of water-soluble fertilizers. And there are different classification standards and methods of water-soluble fertilizers. But according to the physical form of the fertilizer, we can divide the water-soluble fertilizers into two categories. One is liquid water-soluble fertilizer, and the other is solid water-soluble fertilizer. You can get more information about two water soluble fertilizers from the following.

Liquid Fertilizer

Compared with traditional fertilizers, liquid water-soluble fertilizers have inherent advantages. You can flexibly adjust the production formula according to production needs. Moreover, it dissolves quickly and is easier for plants to absorb nutrients than solid fertilizers. It is an ideal choice for fertilizer for irrigation systems.

Solid Water-Soluble Fertilizer

Firstly, it is easy to master the production method of solid water-soluble fertilizer. In addition, it is more convenient to store and transport the solid water-soluble fertilizers. In the production of solid water-soluble fertilizers, you can mix different types of nutrients at one time to achieve one fertilizer with multiple effects.

Both liquid water-soluble fertilizers and solid one have their own benefits. You can choose the right water-soluble fertilizers to produce according to your production budget and raw materials.

How Do You Make The Liquid Water Soluble Fertilizer?

The production process of liquid water-soluble fertilizers is relatively simple. The following is the specific process flow of the liquid fertilizer which can be your reference.

Raw Material Collection

When making water liquid fertilizer, you can use animal urine or biogas slurry to produce organic water-soluble fertilizers. You can also choose straight fertilizers like nitrogen fertilizers or compound fertilizers.

-

For Animal Urine And Marsh Fluid

-

For Single Nutrients Fertilizers Or Multi-Nutrient Ones

When using the granular fertilizer as the raw materials of the liquid fertilizer, you need to use a pulverizer to crush and dissolve them in water. Butdoing so, you can speed up the dissolution rate and shorten the preparation time before production.

Because there are simple nutrients in the animal urine and straight fertilizer and compound fertilizer, you should add some other substances to supplement the nutrition of liquid fertilizer. For example, for animal urine, you need to add peanut bran and soluble glycogen in the ingredient tank. At the same time, in order to promote fermentation, you also need to add anaerobic fermentation bacteria.

Liquid organic water-soluble fertilizer has different fermentation methods from traditional organic fertilizer. You should adopt the sealed anaerobic fermentation method. SX specially designed an anaerobic fermentation tank for the liquid fertilizer anaerobic fermentation. The main body of such a fermentation tank is composed of an inner tank, a heat conducting layer and an insulation layer, which can effectively ensure the effect of anaerobic fermentation. And there is an automatic exhaust system on the fermentation tank, which can exhaust the carbon dioxide produced by anaerobic fermentation.

For the packaging of liquid fertilizer, we can provide you with fully automatic filling line. By using the automatic packing line, you can improve the packaging efficiency.

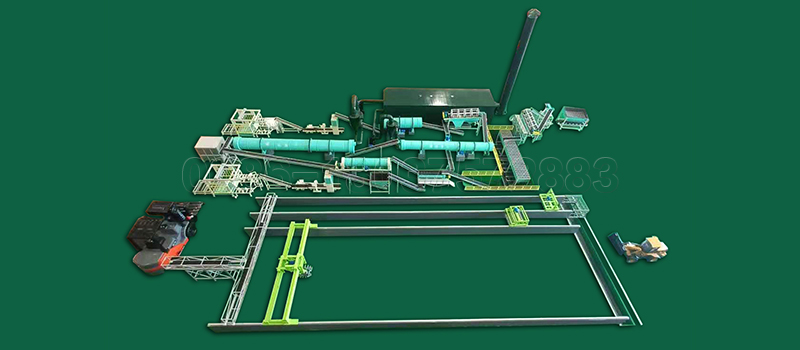

SX designed a complete set of production equipment specifically for the production of liquid fertilizers. We can customize the production line of liquid water-soluble fertilizers for you according to your production budget and capacity.

What Is The Powder Water Soluble Fertilizer Making Process?

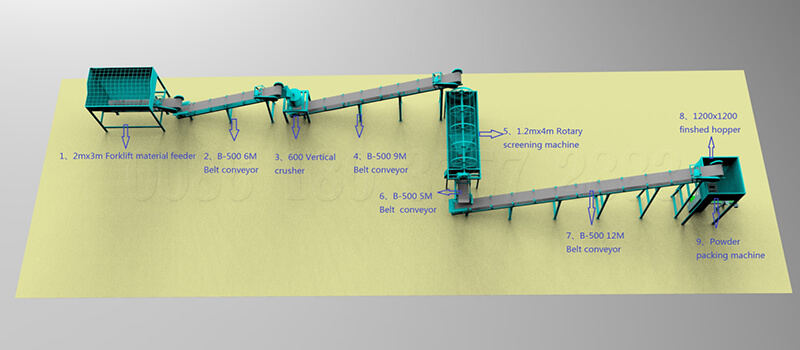

When making powder water-soluble fertilizers, you mainly adopt physical mixing method. You can learn about the specific production process of powdered water-soluble fertilizers from the following.

There is no impurity removal process in the powdery water-soluble fertilizers production line. This is because the purity of water-soluble fertilizers is determined by the purity of raw materials. To produce high-purity and efficient water-soluble fertilizers, you should choose high-quality raw materials.

The Detailed Process To Make The Granular Water Soluble Fertilizer.

Granular water-soluble fertilizers are produced by entering the granulation line of powder water-soluble fertilizers. Therefore, the production process will be more complicated than that of the powder ones. The followings are the specific production process of granular water-soluble fertilizers.

There are many advantages of making the water-soluble fertilizers pellets. For example, you will reduce dust pollution and storage and transportation costs effectively. Therefore, it is profitable to make the granular water-soluble fertilizers.

Through the above, you can know more about the water-soluble fertilizers. You can make two water soluble fertilizers according to the different raw materials. You also have a deeper understanding of the production process of liquid, powder and granular water-soluble fertilizers. When planning to produce expanded fruit type, disease-resistant type and rooting type water-soluble fertilizers, you can contact us. Then we will design the corresponding production plan according to your needs.

Error: Contact form not found.