In August 2021, FPC sells a complete set of organic fertilizer production line to Sri Lankan fertilizer manufacturer. The whole line can produce 10 tons of organic fertilizer granules per hour. The following is the detailed communication process with Sri Lankan customer. The data is just for your reference. If you want to buy a set of customized organic fertilizer production line, yo can contact us. We will provide you with the tailored design solution and reasonable price.

The customer from Sri Lanka uses the chicken cage bedding to produce organic fertilizer. The bedding materials are the mixture of chicken manure and sawdust. They are common raw materials for organic fertilizer production. Therefore, our organic fertilizer making machine can be used for chicken cage bedding disposal. When purchasing the fertilizer production line, you can tell us the type and amount of your raw materials. In this way, we can recommend the most suitable machine to you.

There are two common ways for chicken manure disposal. One is to process the chicken manure into powder organic fertilizer. And the other is to turn the chicken manure into granular organic fertilizer. We know about the amount of raw materials and the farm scale of Sri Lankan customer. We suggest him to produce the chicken manure organic fertilizer pellets. As experienced fertilizer equipment manufacturer, we can give you some professional advice about fertilizer production.

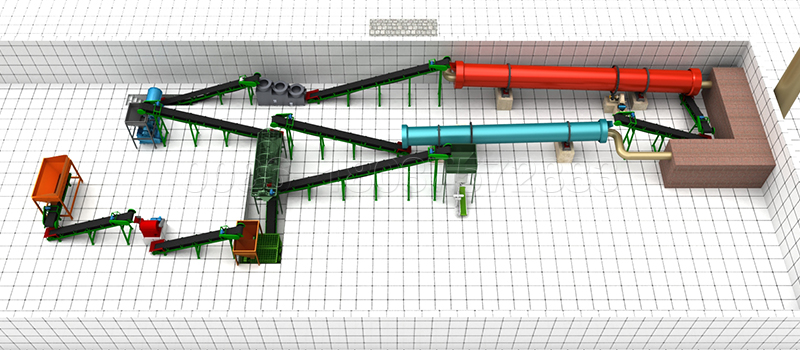

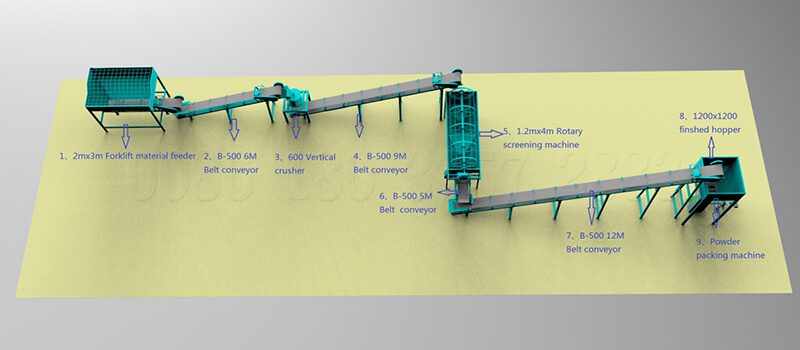

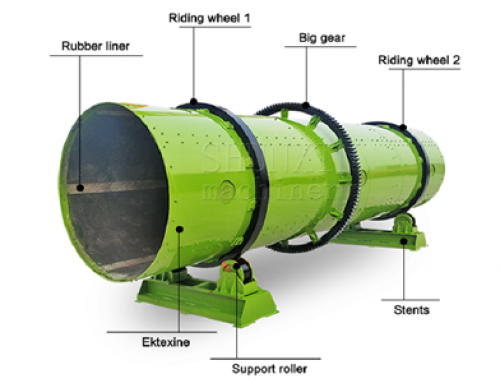

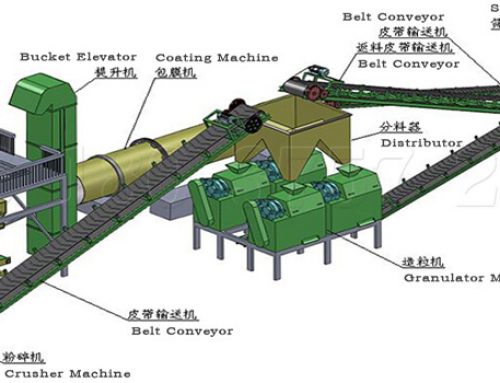

From the above, we recommend the granular chicken manure organic fertilizer production line for this customer. FPC produces 500kg/h-20t/h organic fertilizer production line to meet customers’ production requirements. According to the daily chicken manure output of the customer’s farm, we recommended a 10t/h organic fertilizer pellet production line to him. You can get the customized powder and granular organic fertilizer production line from FPC. Welcome to consult.

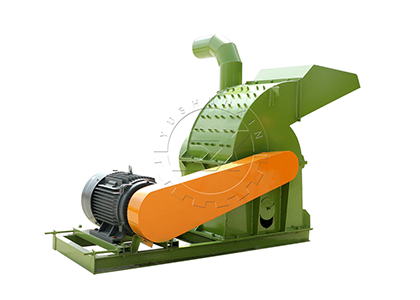

When fermenting the chicken manure, you can add agricultural waste like soybean meal,straw, wood sawdust into it. By doing this, the customer can adjust the raw materials pile to speed up composting. What you should note is that you should use the mixing machine to make the auxiliary materials distribute evenly. For the straws, you need to use the fertilizer crushing machine to process them. Then you need to use the manure compost turner machine to turn the raw materials pile regularly. After about 15 days, you can get the fermented chicken manure. Different raw materials need to be processed with different ways. For example, fresh cow manure need to dewatered through the solid liquid separator before fermentation. Therefore, you need to tell us your raw materials. Then, we will provide you with suitable production process and machines.

Because the price of complete granular organic fertilizer production line is related to the amount and types of the making machines. We recommend the most suitable machine for him. What’s more, we design the whole line with the best solution. After agreeing on the equipment that needs to be purchased, the customer signs a deal contract with us. We produce many organic fertilizer production lines. All of them are on sale at the favorable price. Therefore, you can buy a complete set of organic fertilizer production line at the best cost. Of course, we will also off the best production line for you.

The above is the communication process with the Sri Lankan organic fertilizer producer. The data is for your reference only. You can contact us for newest information of the machine and production line. FPC is an old-brand fertilizer equipment manufacturer. We have been engaged in design and installation of fertilizer production line for many years. You can buy liquid fertilizer production line, compound fertilizer production line, urea based compound fertilizer production line and organic fertilizer production line from here. Welcome to our website for free inquiry. We will provide you with professional advice and fair quoted price.

Error: Contact form not found.

Leave A Comment

You must be logged in to post a comment.