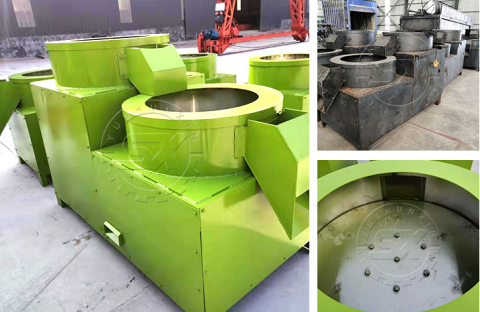

Fertilizer polishing machine is an important machine while making the fertilizer granules. It can improve the physical properties like strength and appearance of fertilizer pellets. Therefore, in the granular fertilizer production line, many fertilizer makers will use the polishing machine. For improving the efficiency, we improve the structure of SX fertilizer grinds polishing equipment, such as frame, dimension,models. We also design different types of the polishing equipment for different raw materials. What’s more, we have chicken manure polishing machine, cow dung fertilizer polishing equipment and other animal manure polishing machines. You can choose it based on your raw materials. Our fertilizer ball polishing equipment can also adapt to different fertilizers production lines, like organic fertilizer, compound fertilizer. Besides, we can provide you some tips to maintain the machine. As the old-brand fertilizer equipment supplier, we have the perfect service system. Once choosing SX, you will get a perfect purchasing experience.

For increase the competitiveness of fertilizer granules, the fertilizer producers would like use a fertilizer round making machine. But why? Let’s compare the the fertilizer granules before and after granulation and rounding.

After being granulated by the fertilizer granulation machine, the powder organic manure can be formed into ball shape. However ,whatever which kinds of fertilizer granulators you use, there is a common problem that all the fertilizer particles have an uneven appearance. What’s more, the strength of fertilizer granules is not strong enough to withstand the friction and pressure among the particles.

The fertilizer round polishing machine can make the fertilizer granules surface more smooth and beautiful. After being polished, the fertilizer granules will have a better fluidity. Therefore, the polished fertilizer granules have strong competitiveness of sales market.

Because the granules are polishing many times in the ball-shaping cylinder. Therefore, as the fertilizer manufacturer,you can use the fertilizer polishing machine to increase the fertilizer sales. That’s why polishing machine can improve the competitiveness of fertilizer products.

Top 5 Technical Design Highlights On Sx Fertilizer Polisher.

You will get more information about the SX ball shaping machine advantages through the above. Because of these advantages, there is high sales of the fertilizer polishing machine at home and abroad.

Here is the technical parameters about the TDPY- 800,TDPY-1000,TDPY-1200,TDPY-1500fertilizer polishing machine. The data is just for your reference.

| Model | Capacity | Power | Disc Diameter | Dimension(mm) |

|---|---|---|---|---|

| TDPY- 800 | 1-2t/h | 5.5kwx2 | 800mm | 2800x920x 1290 |

| TDPY- 1000 | 2-3t/h | 5.5kwx2 | 1000mm | 3100x1020x1390 |

| TDPY- 1200 | 3-5t/h | 7.5kwx2 | 1200mm | 3400x1120x1490 |

| TDPY- 1500 | 5-8t/h | 11kwx2 | 1500mm | 3200x1550x1600 |

Top 6 Fertilizer Polishing Machines For Sale

If you want to make chicken manure bio-fertilizer more salable, you should adopt this type of chicken droppings polishing machine.Because the chicken manure is a kind of fertilizer with high nutrients content and good effect. There are many farmers who want to buy the chicken manure fertilizer. You can use a fertilizer ball forming machine to make your chicken manure fertilizer pellets have a beautiful appearance. Thus your chicken manure pellets are more marketable and competitive.

There are many pig manure fertilizer manufactures. How can i make my pig manure fertilizer stand out? This problem will make you very distressed. Don’t worry, our polishing machine can solve this problem. By using a round-polishing machine, you can make your pig manure fertilizer in appearance, hardness, fertilizer efficiency to a higher level.

Our cow dung polishing machine has the function of drying. The cow manure is a kind of fertilizer with high water content. By using the cattle dung round-shaping machine, the water content in the manure can be reduced. This function of the polishing machine can cut the cost of drying process.

Just like its name, there is only one cylinder in the polishing part. This kind of polishing machine is suitable for small-scale manufacturers. If your expected output is 1-2t/h, we advise you to use this type of the manure polishing machine. In this way, you can spend a little money to buy products you are satisfied with.

It can be seen from the name that the main polishing part is composed of two cylinders arranged in sequence. Compared with the single disc throwing machine, the output of double disc polishing machine is larger. If your production scale is 2-5t/h, we recommend you to use this one. It can also be used with a variety of granulators to improve production efficiency.

This type of rounding machine has a large processing capacity and is suitable for larger-scale fertilizer producers. If you want to produce 5-8t polished fertilizer pellets per hour, the multi-disc round fertilizer polisher will be your best choice. It is worth noting that the number of discs can be customized according to your production needs.

How To Make The Polishing Machine Have a Long Service Life

Regular Maintenance

Long time use of polishing machinery will lead to wear of some parts. So you need to check and repair the polishing machine regularly. Regular inspection of the polishing machine can ensure the smooth production. After you buy our round machine, we will provide you with maintenance and replacement services.

Regular Cleaning

Our round-polishing machine can carry out continuous work for a long time. However, what you should pay attention to is that clean the inner cylinder after the manure polisher finishes its work. By this way, you can avoid the bad impact on the material polishing at the next time. Cleaning the machinery can not only ensure product quality, but also not waste materials.

Once Choosing SX Round Fertilizer Polishing Machine, You Can Experience Our First-Class Service Immediately

Error: Contact form not found.