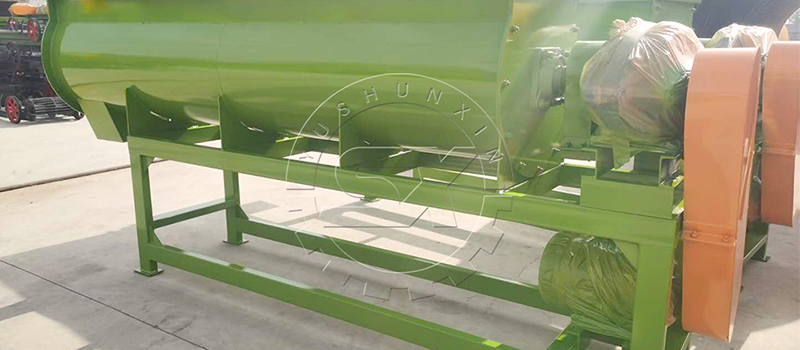

In order to make the fertilizer nutrients distribute evenly, you should use the fertilizer mixing machine. There are many types of the mixing machines in SX. We have improved the mixer structure to improve the working efficiency. As the old-brand fertilizer production equipment producer, we can provide you with some advice about how to select and operate the mixer.

Because of the mixing machine produced by SX with high quality, more and more fertilizer manufacturing factories would like to use the SX fertilizer blending machine. You can know more about the SX mixing equipment from the following.

Our mixing machine is a kind of the high working-efficient fertilizer production equipment. When designing the mixing blade, we adopt the double helix structure. Therefore, when mixing the raw materials, you can be easy to blend them evenly.

While producing the mixing machine, we use high-strength and wear-resistant steel to make the mixing blades which is contacted with the raw materials directly. Therefore, you can use the mixer produced by SX for a long time.

We adjust the minimum gap between the rotor and the mixer housing to close to zero while producing the machine. Therefore, when using the mixer produced by sx, you can reduce the waste of materials and increase the output of fertilizer.

Through the above, you can know more about the advantages of the SX mixing machine. It is precisely because of these advantages that our customers highly praise our mixing machine.

Here is the technical parameters about the SXSJ-0830,SXSJ-1050 double shafts mixing machine. The data is just for your reference.

| Model | Power(kw) | Reducer Model | Outer Diameter of Mixing Shaft(mm) | Mixing Speed(r/min) | Dimension(mm) |

|---|---|---|---|---|---|

| SXSJ-0830 | 11 | ZQ350-31.5 | 420 | 35 | 3700×800×750 |

| SXSJ-1050 | 22 | ZQ500-31.5 | 650 | 35 | 6200×1300×1200 |

How To Choose The Fertilizer Mixer For Your Production Line?

In order to choose the right mixing machine for your fertilizer production line, you should consider the budget and the capacity of the fertilizer production. You can refer to the following.

The Budget

Your budget will affect the machines configuration in your fertilizer production line. For example, you set up the organic fertilizer production line with the budget of $45,000. You can produce the 5 tons of the powder organic fertilizer with $45,000 production line. The sxwj-90 mixing machine is more suitable for the $45,000 organic fertilizer production line.

The Capacity

The fertilizer production capacity is another aspect which affect the mixing machine selection. You can buy the right blending machine based on productivity of your fertilizer plant. For instance, if you want to make the 2-3 tons of the organic fertilizer, you can choose the sxwj-70 fertilizer mixing machine.

The data is just for your reference. You can provide us with your actual fertilizer production plan. We will recommend the most proper mixing machine based on your budget or the production capacity for you.

The double roller blending machine is an effeient fertilizer production machine. It is dispensable for organic and compound fertilizer production. You can know the working process of double shaft blending machine from the following vedio.

How To Operate The Fertilizer Mixer More Safely?

For reducing the maintenance cost of the fertilizer mixer, you should use the machine correctly. But how do you use the mixer? there are four tips you can refer to while using the blending machine.

Through following the above four tips, you can operate the blending machine more safely. In addition, you can make the machine mix the raw materials more evenly,which is conducive to the next fertilizer production process.