Fertilizer granulator machine price changes with its types and specifications. According to granulation manufacturing process, fertilizer pellet making machines can be divided into two types. One is wet granulation machine, and the other is dry granulation machine. FPC, as granulator manufacturer, has dedicated in these two types of fertilizer granules making equipment design, production and improvement for many years. What’s more, FPC wet and dry fertilizer pellet making equipment have been sold in US, Indonesian,Pakistan,Peru and other countries. Therefore, customers can choose many cost-effective organic compound fertilizer granulators from FPC.

The machines used for fertilizer granulation

Fertilizer flat die granulator, double roller extrusion granulator, fertilizer polishing machine, rotary drum granulator, rotary gear drum granulator, pan granulator and new type organic fertilizer granulator.Fertilizer Granulator Machine

How Much Are the Wet Fertilizer Granulation Machines

The wet fertilizer granulator machine price depends on selected granulator type and production capacity. There are four kinds of wet granulation machine you can select. They are drum granulator, churning granulator, drum and churning granulator, pan granulator. In addition, each one has different production capacities and technical specifications. From the following, you can know more about wet fertilizer granulator machines.

The above data about fertilizer granulation machine price is just for your reference. The machine price will fluctuate with the fertilizer production equipment market. We will offer the customers latest fertilizer wet granulation machine price. In addition, customers can buy efficient wet granulation machine at preferential price.

What Is the Prices of Dry Granulation Machines?

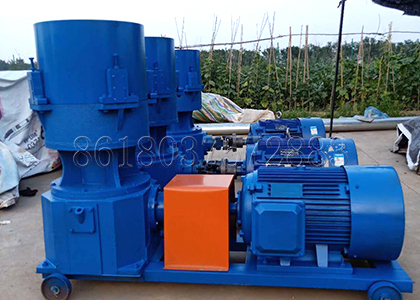

The fertilizer drying granulation machine price is related to the production yield and machine specifications. When applying dry granulation method, you can choose flat die granulation machine and double roller extrusion granulation machine. You can get more information about them from the following.

The mentioned data is for your reference only. There are flat die granulator and roller pressing granulator with different specifications and yields in FPC. All of dry fertilizer granulation machines are on sale at perfect price.

What Are Differences Between Dry Granulation Machines And Wet Ones?

In the organic fertilizer production industry, the granulation process is often involved. Therefore, you need to use the granulating equipment. There are various types of granulation equipment on the market. Generally, they can be divided into dry granulator and wet granulator. Through understanding working principle of granulation machines, you can produce quality fertilizer pellets.

Compared with wet granulation method, the dry granulation method will cost less. That’s because there is no drying process after granulation. Therefore, fertilizer pellets manufacturers can coat the granules directly after granulating process.

How to Choose the Right Organic Fertilizer Granulation Production Equipment?

For different granulation processes, FPC company designs and produces the above six types of fertilizer granulating machines. Then, how to buy the right granulating machine for your fertilizer equipment? It depends on your production budget and granulation process. The following can be your reference when choosing the fertilizer granulator equipment.

What Is the Best Machines for Fertilizer Plant with Limited Budget?

If your budget is limited, you can consider to buy the pan granulator, flat die granulator and double roller extrusion granulator. While expanding the scale of fertilizer granules production line, you can buy one or two more same granulator machines. When producing the dry fertilizer pellets, the flat die pelletizer and double roller press pelletizer will be your best choice. They will save the cost of drying process.

For Large Scale Organic Fertilizer Granules Production Line, Which Granulator Is Best?

Among various types of granulation machines, rotary drum granulator machine is more suitable for large scale organic fertilizer pellets production. From the above, you can know that there are many technical parameters of drum granulation equipment in FPC company. When purchasing the large scale granulating machine, FPC drum granulator will be your better choice.

The above is for reference only. You can buy the most suitable fertilizer granulation machine through consulting with us. We will recommend the best organic fertilizer granulation machine for you. What’s more, our technical personnel will provide you with granulator machine installation and operation skills.

Why FPC Fertilizer Granulation Machine Are Cost-Effective Equipment?

In addition to meet customers’ different production requirements, fertilizer pellet making machine produced from FPC also have some significant advantages, such as high working efficiency, long service life, low energy consumption and strong adaptability. Precisely because of these advantages, FPC fertilizer granulation machines are called cost-effective production equipment. Their advantages are as follows.

High Working Efficiency

The granulation rate and pellet size are important criteria to measure the working efficiency of granulation machine. The wet granulation equipment made by FPC has over 90% pelleting rate. The granulation rate of FPC dry pellet making machines is over 85%. As for pellet size, customers can use FPC fertilizer pellet making equipment to produce 3-8mm fertilizer granules.

Long Service Life

In order to reduce the maintenance cost, we use the quality materials to produce the fertilizer equipment. Each fertilizer granulation machine is equipped with special design to prolong its working life. For example, the gear on drum-churning granulator is made of anti-wear carbon steel. There is anti-corrosive rubber or 304 stainless steel inner lining in the drum pelletizer.

Low Energy Consumption

We equip the granulation equipment with the most energy-saving drive device. In this way, the fertilizer pellet making machine not only has powerful drivers but also has low energy consumption. For example, 8-15t/h drum fertilizer pelletizer can consume 18.5kw per hour. Its power is equivalent to that of the disc granulator with the largest yield.

Strong Adaptability

As mentioned above, the double roller extrusion granulator can process ammonium bicarbonate, ammonium chloride, monoammonium phosphate, etc. Other fertilizer granules making equipment also has strong adaptability. In addition to granulating organic materials like animal manure, crop straw, the drum fertilizer pellet machine is also suitable for granulation of DAP,SSP,MOP, etc.

The above is just for your reference. However, the above four points can indicate that FPC fertilizer granulation machine price is reasonable. What’s more, we have our own fertilizer equipment production factory. Therefore, you have the chance to get the fertilizer granulation machine at factory price.

How to Make the Fertilizer Granules More Salable After Granulation?

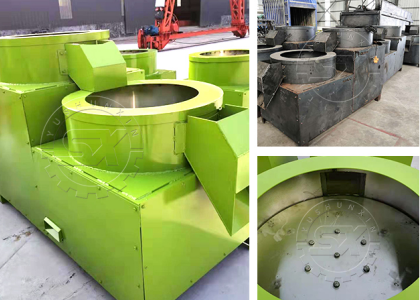

After granulation with drum, churning or pan granulator, you might get fertilizer pellets with different sizes and uneven surface. To make fertilizer pellets more salable, you need to use the fertilizer polisher. You can know the more detailed information about the fertilizer polishing machine from the following.

Multi Grade Polishing

Considering customers’ different production capacities, FPC manufactures one grade polishing machine, two grade polishing machine and multi grade polishing machine. Customers can select the fertilizer round shaping machine according to the pellet surface situation and strength.

Various Types

We produce different types of fertilizer polishing equipment according to different fertilizer making plants. For organic fertilizer plant, you can get cow dung polishing machine, chicken manure polishing machine, sheep manure polishing machine,etc. You can also find compound fertilizer polisher in FPC.

Different Yields

You can get fertilizer polishing machine with yield of 1-8t/h in FPC company. There is SXPY-800, SXPY-1000, SXPY-1200, SXPY-1500 fertilizer polish machine you can choose from. Each of them has a disc with different diameters. In addition, we can provide you with customization service.

The above is for your reference only. After using polishing machine, you can get fertilizer granules with stronger hardness and more beautiful appearance. In this way, you can improve the fertilizer pellets competitiveness to make more benefits.

Drum Granulation Production Line at Best Price for Thailand Fertilizer Production Customer.

Our granulation machine has been sold at home and abroad for many years. Our machine has been highly praised by fertilizer manufacturers from all over the world. Here is a successful case about drum granulation line in Thailand.

When dealing, we give some discount to the Thailand fertilizer producer. Therefore, you can also get the efficient granulation line at preferential price from FPC fertilizer equipment manufacturer. What’s more, we can customize the granulation line according to the customers’ requirements.

FPC is a fertilizer equipment production company with 15-year experience. Therefore, we can provide granular fertilizer manufacturers with efficient fertilizer pellets production machines. Customers can get fertilizer granulator machine at minimum cost from FPC.