Fertilizer coating machine is mainly suitable for granular fertilizer production line. The machine plays an important role in the granular fertilizer production business. Because there are many advantages of coated fertilizer, such less caking and nutrient loss. For making the granular fertilizer coating process with high efficiency, SX designs the rotary coating machine with high performance. The SX rotary drum coating machine has wide adaptable to the materials that will be coated. Whether produce organic fertilizer or compound fertilizer, you can apply the coating equipment.

After drying and cooling process, there are some problems on the fertilizer granules, like uneven surface, nutrient loss and caking. How to do with these problems? There is a granular fertilizer coating machine designed by FPC company to remove these disadvantages. Though the fertilizer granules coating machine looks like a drying machine, their functions are different completely. You can know about the coating machine from the following.

From the above, you can know that the coated fertilizer granules have more advantages than uncoated fertilizer granules. Therefore, you can buy an coating machine when running a large scale granular fertilizer production line. In this way, you can make more benefits from producing the coated fertilizer pellets.FPC has been dedicated in fertilizer equipment production over 15 years. We produce many quality fertilizer coating machine for granular fertilizer production. Our coating machine has strong adaptability. You can use it to coat the organic,inorganic and compound fertilizer pellets. What’s more, they are on sale at the affordable price. Therefore, you can buy different technical specifications of coating machine at the best cost from FPC fertilizer equipment manufacturer. You can also contact us for customized granular fertilizer coating machine.

How Does The Fertilizer Coating Machine Work?

When buying the fertilizer rotary drum coater, you should understand its working principle and working process. You can get more detailed information from the following.

Working Principle

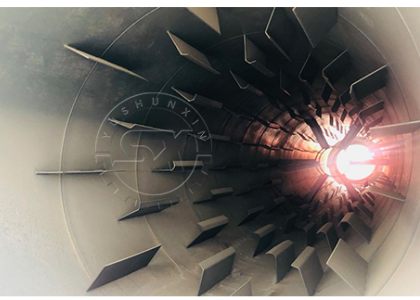

The main motor drives the belt and pulley. Then the belt and pulley drive the driving shaft through the reducer. The split gear installed on the driving shaft and the big gear ring fixed on the machine body rotate in opposite directions. Through the coordinated operation of these parts, the whole machine of the drum coating machine can start to work.

Working Process

When coating, The material enters the cylinder from the feed port. Then the material combines physically with the additives which is sprayed by the pipe to achieve the coating effect. The additives can be slow-release agents, coloring agents and beneficial bacteria. In the end, the filmed fertilizer pellets will flows out from the discharge port.

The rotation rate, inclination angle, coating time, temperature, coating thickness and the use of binder are all the influencing factors of coating process. When debugging, according to your actual production needs, we will provide you with appropriate process parameters to ensure the production of good coated fertilizer.

What Are Structural Advantages Of The Fertilizer Coating Machine?

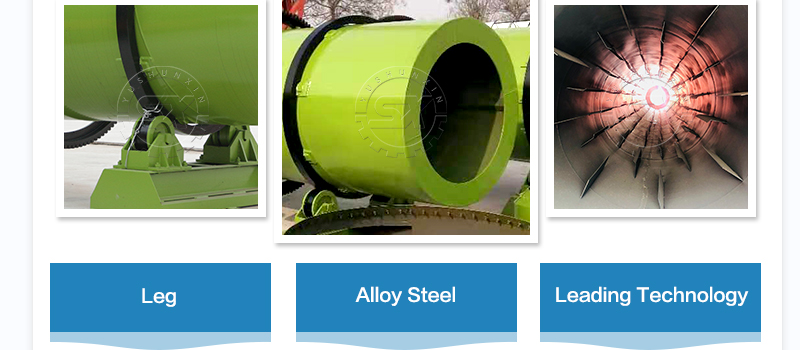

In addition to understand the machine working process, you should also be clear about the structures. There are four major working parts of the rotary fertilizer coating machine. You can learn more about the structural features from the following.

Fertilizer Coating Machine Drum

The rotary drum is the core part of the coating equipment. The material of the drum part is welded by several medium carbon steel plates. The production of this material is strictly controlled by quality. The whole main part of the material is corrosion-resistant and strong. Therefore, it is not easy to be deformed because of long-term use.

Fertilizer Coating Machine Bracket Part

The bracket supports rotating part of whole body. Therefore, the force on bracket is large. The bracket of our coating machine is welded by carbon steel plate and channel steel. Solid, strong bracket to ensure that body of machinery rotates smoothly. Because the body rotation will produce relatively large friction, both our bracket and cylinder adopt wear-resistant materials.

Fertilizer Coating Machine Transmission Part

This part is also a very important part of the whole machine. Transmission frame material adopts channel steel, this material is strong, durable, quality assurance. The material toughness of the transmission belt is good and it is not easy to disconnect. Both motor and reducer are qualified products that meet ISO standards.

Fertilizer Coating Machine Large Gears

The big gear ring is fixed on the drum. When rotating, it moves with the drive pinion to drive the body to work. Considering that the gear often has to fit with pinion teeth, we choose the wear-resistant materials to produce the gears. What you should note is to lubricate the gears after finishing the production.

4 Important Points For Attention In Operation Of Fertilizer Coating Machine

In order to ensure that the coating equipment can be used effectively for a long time, you need to pay attention to some points while using the machine. The following can be your reference.

3 Outstanding Advantages Of SX Fertilizer Coating Machine.

The fertilizer filming machine produced by SX is popular with the many fertilizer producers. That is because they can get many benefits from using it. There are also many outstanding advantages on the SX filming machine. The advantages of the SX fertilizer filming equipment are as follows.

The above three aspects are the advantages of the SX coating machine for sale. You can also come to visit our factory and see the coating machine production process on site. We will explain the structure and operation principle of the coating machine for you.