Detailed Pan Granulation Process

The above data are just for your reference. The disc granulator manufactured from FPC has high working efficient and high granulate rate. For example, FPC disc granulator can granulate the fertilizer continuously. You can produce 0.02t-6t fertilizer pellets per hour by using pan granulator. What’s more, pellet rate of FPC plate granulator is more than 93%.

Two Methods to Adjust Granules Size

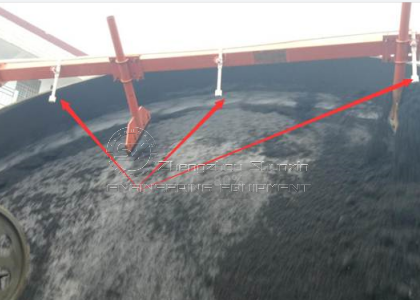

In addition, you can adjust the fertilizer pellets size with the pan pellet making machine. There are two ways to adjust the fertilizer granules size. One is control the moisture. You can adjust the spray system to control the water content. The more water, the bigger granules. The other is to adjust pan slop angle. Sharper slope, smaller size.

Error: Contact form not found.