Liquid fertilizer production process is to make the organic wastewater like animal urine into liquid type organic fertilizer. FPC has been dedicated in organic liquid fertilizer production line design and production for many years. We can summarize specific liquid fertilizer manufacturing procedures for you. The liquid organic fertilizer manufacturing process can be divided into three steps, get the original liquid organic waste, remove impurities in organic wastewater, fermentation of liquid organic waste. You can know the detailed production process from the following.

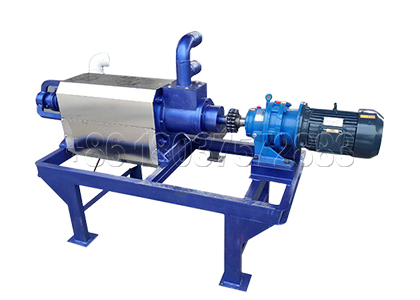

Some raw materials like well water and biogas slurry can be used for liquid fertilizer production directly. However, raw materials like animal manure need to undergo solid-liquid separation before they can be used in liquid fertilizer production. Therefore, you need to use the dewatering machine for livestock and poultry manure disposal. In addition, while separating the waste water from solid materials, you may need to use the crushing machine to treat the caked animal manure. After the solid and liquid separation, you can put the waste water into the tanks which are built in advance for sedimentation and overflow.

Following the former step, you fill the organic waste liquid into the sediment and overflow tanks after solid-liquid separation. This step is to remove big impurities like stones. After a while, you can pump the animal wastewater into the filter devices through the centrifugal pump. FPC liquid fertilizer production filter device can remove the micro impurities like grass scraps. After filtering, there are still harmful microbes like e. coli in the animal manure waste liquids. Therefore, the waste solution from these animals manure should be sterilized before being used in liquid fertilizer production. The UV sterilization device is required at this time. After sterilization, the impurities in organic wastewater will be removed completely. Then, you can use these liquid materials to ferment into organic liquid fertilizer.

The organic liquids will be pumped into the liquid fertilizer mixing systems after removing the impurities. In order to ferment the organic wastewater quickly, you should add some auxiliary materials and fermentation agent into the mixing equipment. You can use the fertilizer crushing machine to treat bulk auxiliary materials. In this way, you can speed up materials dissolution to improve the production efficiency. After mixing, the mixture can be pumped into the chelating tank to anaerobic fermentation. You can get the fermented liquid organic fermentation through 72-hours fermentation, What’s more, you can deploy an organic liquid fertilizer canned packing line to pack the liquid fertilizer products. Then you can sell them to make more benefits.

The above is the complete production process of liquid organic fertilizer. You can also contact with us for more detailed information. FPC is an old-brand organic fertilizer equipment production company with years of experience. In addition to offer professional suggestions, we can also provide you with quality solid-liquid separator, fertilizer crushing machine and whole set of liquid fertilizer production line. You can use our production line to make the rooting liquid fertilizer, expanded fruit liquid fertilizer and disease-resistant liquid fertilizer. Therefore, FPC liquid fertilizer equipment and production line will be your better choice. Welcome to our website for consultation.

Error: Contact form not found.