If you plan to set up an plant of organic fertilizer production with the budget of $600,000, what should you do? What kind of organic fertilizer making machines should you buy? What about the production site area? FPC is a professional fertilizer equipment manufacturer with over 15 years of production experience. We design and install the while fertilizer production line for small or large organic fertilizer plant. Therefore, we will give you some helpful advice about set up an organic fertilizer plant with the budget of about $600,000. The details are as follows.

What machines should you buy for 20 t/h organic granular fertilizer production line?

When making the granular fertilizer, the production process can be divided into three stages: pre-treatment step, granulation step and after-granulation step. You can know about the machine used in each step from the following.

Pre-Treatment Step

There are dewatering, composting, crushing and screening at the pre-treatment step. When you make the organic fertilizer with the fresh animal manure and high-moist agricultural waste, the solid-liquid separator is needed. As for the composting equipment, you can buy the crawler type compost turner. That’s because it is suitable for the large scale organic fertilizer manufacturer. You can use the vertical type compost shredder or semi-wet materials crusher at the crushing process. When producing 20t/h organic fertilizer per day, the SXGS-2080 rotary fertilizer screening machine is the best for you.

Granulation System

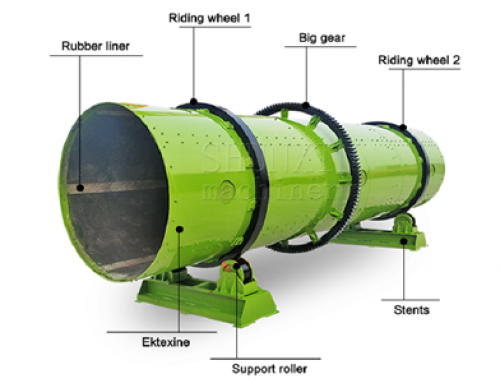

When turning the powder fertilizer into granules, there are multi choices for you. For example, you can use the pan granulator, rotary gear drum granulator and drum granulator, ect. For the 20t/h organic granular fertilizer making line, we recommend the pan granulator and rotary drum granulator. When deploying the whole line with these two granulation equipment, you can save energy consumption and improve the granulation efficiency. Of course, we will design the complete fertilizer production line based on your production site.

After-Granulation Step

After granulation process, there are also many shortcomings of organic fertilizer granules, such as high moisture, lower hardness and less fluidity. Therefore, we usually advise the customer to use the drum drying machine and cooling machine. When improve the granules fluidity, we recommend the fertilizer rotary drum coating machine. After being processed by these machines, the quality of organic fertilizer granules can be improved.

There are also other auxiliary machines which you should buy, like belt conveyor, materials buffering silo, materials returning system and dust removal system. These auxiliary fertilizer making machines can make your production line more efficient. You can email us to get detailed design solution of organic fertilizer production line.

How large of production site should I prepare for 20t/h organic fertilizer production line?

when installing the 20t/h granular organic fertilizer production line, you need rent a 10000 square meters of production area at least. If you build the organic fertilizer processing plant, you need much more place. You need to build a warehouse for storing the finished fertilizer products. At the same, you should prepare a large place for raw material fermentation. When applying groove fermentation and windrow fermentation, the fermentation area will be larger. If you use the organic fertilizer fermentation tank, you can save the production site area but increase the cost. Therefore, you should purchase the organic fertilizer manufacturing machines based on your budget and production capacity.

The above is about the design solution of 20t/h granular organic fertilizer production line. There are also other types of organic fertilizer production lines for sale in our company. You can email us to get the latest price of machines and best design solutions. Welcome to inquiry.

Error: Contact form not found.

Leave A Comment

You must be logged in to post a comment.