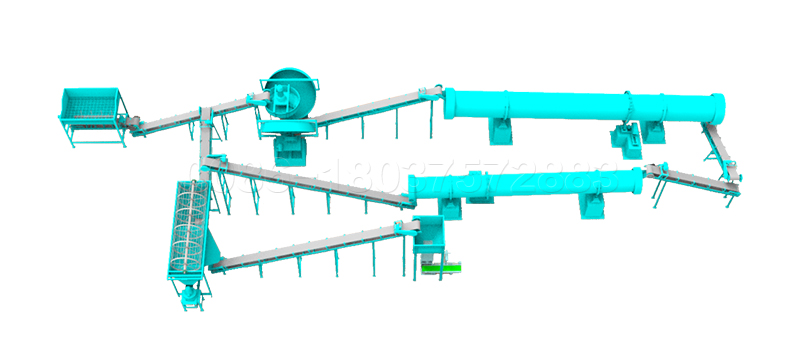

There are two main compound fertilizer production line in the fertilizer production industry. The first one is NPK compound fertilizer. And the second one is BB comound fertilizer production line. From the following, you can know the these two compound fertilizer production process. While selecting the compound fertilizer prodcution equipment, you should be clear about your budget and production capacity. In addition, you should note the produced fertilizer type. Generally, you can make more benefits from making granular NPK compound fertilizer than powder ones. While producing compound fertilizer, there are two points you should know. One is the batching process of the base fertilizer. The other is to process the fertilizers after mixing. While setting up the compound fertilizer production line, SX will be one of your best choices. There are many advantages of SX compound fertilizer production lines, such as high working efficiency, low energy consumption and special service.

For adapting the growth needs of different crops, the fertilizer producers will make two main compound fertilizers. One is NPK compound fertilizer, the other is BB compound fertilizer. There are two whole sets of production lines for these two kinds of compound fertilizer. You can learn more from the following.

Through the above, you can know the production process of NPK and BB fertilizer. According to your budget, you can choose the right compound fertilizer production line. You can also tell us abut your compound fertilizer production plan. We will recommend the suitable fertilizer production line to you.

What Are The Production Line Of NPK Compound Fertilizer And BB Fertilizer?

While running the compound fertilizer production plant, you’d better figure out the production process about the compound fertilizer. When producing the BB fertilizer, there are only four steps. However, the NPK compound fertilizer production process is more complex. There are three stages of the NPK compound fertilizer production line. You can further understand the production process of these two compound fertilizer from the following.

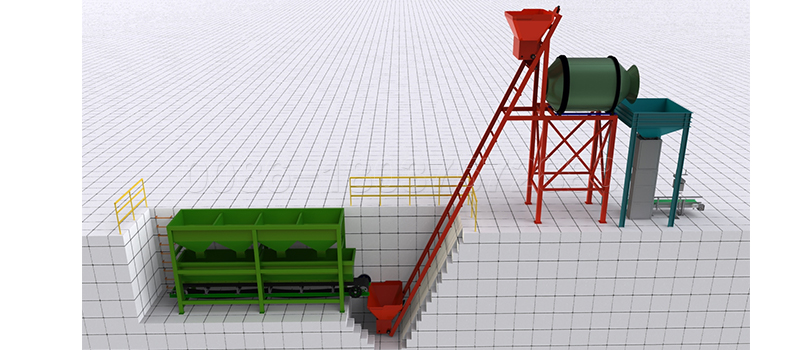

How to design the BB compound fertilizer production Line?

Screen Raw Materials

In order to solve the caking and stratification of the base fertilizer, you need to choose the straight fertilizers with low moisture and uniform particle size. Generally speaking, the particle diameter range of BB fertilizer is 6-18 mm. If you want to screen out the standard fertilizer particles, you need to use the fertilizer sieving machine. The rotary screening machine produced by SX is widely used in the screening of solid materials with particle size less than 300 mm. What’s more, SX rotary fertilizer screening machine has the advantages of high sieving efficiency. For example, the SXGS-2080 screening machine can sieve 10-20 tons of fertilizer per hour.

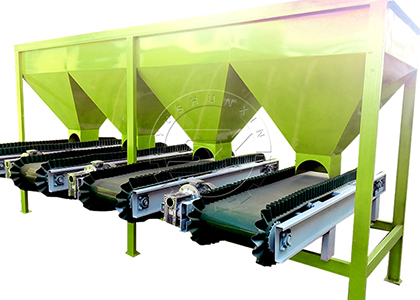

Batch Raw Materials

After screening, you should batch the base fertilizers precisely according to the compound fertilizer production formula. In order to improve the efficiency of the batching process, you can use the automatic batching system. There are two types of the automatic batching machines. One is the static batching machine, the other is dynamic automatic batching systems. Static batching machine has high automation design, but you need to put the base fertilizer into material hoppers manually. However, dynamic automatic batching system has electronic metering equipment design. When you produce BB fertilizer, using it can save manpower.

Mix Base Fertilizer

After completing the batching process, you should blend the straight fertilizers. In order to make the nutrients distribute evenly, we recommend you use the fertilizer mixing machine to blend raw materials completely. SX designs many types of the fertilizer blending equipment with high performance. For example,the SX horizontal mixing machine can process up to 10-15 tons of the fertilizer per hour. There are also two mixer designed specially for the BB compound fertilizer production. They are BB fertilizer mixing machine and drum type BB fertilizer mixing machine. You can choose the fertilizer mixing machine according to your production project.

Pack Finished Products

While packing the BB fertilizer, the automatic packing machine is your better choice. By using the packing scales, it is not only improve the fertilizer production efficiency, but also save the manpower. There are many types of the automatic packing scales machines. When you produce the 5 tons of BB fertilizer per hour, we will recommend you use the packing scale without the bucket. While running the compound fertilizer production line with the capacity of 5-10t/h, the single bucket automatic packing scales is more suitable for your plant. When you produce the 20 tons of compound fertilizer, we recommend you use the double bucket packing scales.

How To Make The NPK Compound Fertilizer Production Line?

How To Determine The Proportion Of Raw Materials?

In general, the proportion of raw materials is determined by the local fertilizer selling market demand and local soil test results. Therefore, you should determine the compound fertilizer production formulation through scientific calculation. Then you complete the batching of various materials according to a certain proportion by using the fertilizer batching system

After Straight NPK Materials Batching, What To Do Next?

The raw materials batched by the fertilizer batching system need to be mixed evenly. Because the more evenly the fertilizer is mixed, the better effect of the fertilizer will have. Usually, the NPK fertilizer manufacturers choose the horizontal mixer and disc fertilizer mixing machine.

How To Do With The Caked Fertilizer In NPK Fertilizer Production?

The reason for crushing the evenly mixed caked fertilizer is to prepare for subsequent granulation. In order to make the effect of fertilizer crush better, we recommend you to use sx chain crusher and cage crusher. These two crushing machines are specially designed for compound fertilizer production.

Everything’s Done? Here Comes With The Key Process: NPK Granulation

The crushed fertilizer is delivered into the granulator through the belt conveyor for granulation. The fertilizer granulation is the key process in NPK fertilizer production. For the granulation process, there are many fertilizer granulation machines in SX you can choose. While you produce the 15-30 tons of the compound fertilizer per hour, the SXZGZ-3210 rotary drum granulation machine is more suitable for your production line. When you run the fertilizer production line with relatively small scale, we recommend you use the pan pellet machine machine. Because the disc granulation machine is cost-effective granules making making machine for the small scale production line. You can also choose other granulation equipment according to your budget and production capacity.

How To Separate Qualified And Unqualified Fertilizer Particles?

The semi-finished fertilizer particles are preliminarily screened by the screening machine. Qualified fertilizer granules are delivered to the next process. However ,the unqualified fertilizer particles needed to be sent back to the mixing process for reprocessing. The screening machine you can choose is the rotary screening machine.

How To Process The Qualified Fertilizer Granules After Screening?

After screening, qualified fertilizer particles are sent to the drying machine for drying by the belt conveyor. The main purpose of drying the moisture in fertilizer particles is to enhance the strength of the particles. The dried fertilizer has the characteristics of pressure resistance and wear resistance. So The dried fertilizer particles are easier to store and transport. When drying, you can choose sx rotary dryer. It has the advantages of high output, large processing capacity and low energy consumption.

How To Get The Dried Granules Cooled?

The fertilizer particles are easily to be agglomerated because of the high temperature after drying process. Hence, the fertilizer granules need to be cooling for packing. When the fertilizer should be cooled, you can choose the rotary drum cooler.

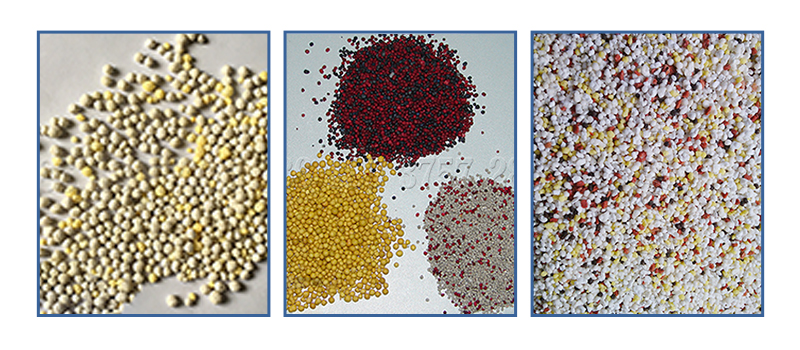

How To Make Your NPK Granules Fertilizer More Colorful?

In order to obtain more benefits from compound fertilizer production, many compound fertilizer manufacturers will coat the finished compound fertilizer particles. The coated fertilizer particles will have a smooth, round and beautiful appearance. Therefore, you can improve the appearance of fertilizer particles by coating them with a coating machine.

Pack Granules Automatically, Let You Sell Your Npk Fertilizer Efficient

The finished compound fertilizer particles will be transported to the material silo for packaging. These finished fertilizer granules will be packed by automatic packing scale. Then the packed fertilizer is stored by automatic palletizing machine. Automatic packing scale and automatic palletizing machine have the functions of improving working efficiency and reducing manpower.

How To Choose The Production Equipment For The Compound Fertilizer Production Line?

When selecting the compound fertilizer production equipment, the budget, production capacity and fertilizer type can impact the machine specifications you can choose. You can consider these aspects while buying the fertilizer machines. You can know more detailed information from the follow.

Through the above, you can choose the right type of the compound fertilizer production equipment for your production line. You can also provide us with your plan about the compound fertilizer production project. We will recommend the fertilizer production machine with proper specification to you.

4 Reasons Tell You Why Granular NPK Compound Fertilizer Is Better Than The Powder Ones

In the compound fertilizer sales market, the shape of compound fertilizer is mostly granular. Four reasons why fertilizer producers mainly produce fertilizer particles are as follows.

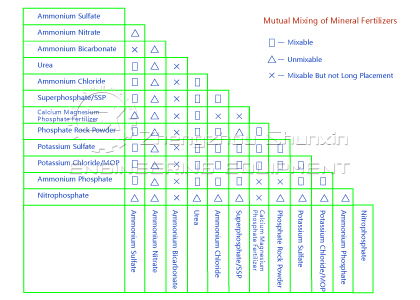

Two Main Points Are What You Should Note While Setting Up The Compound Fertilizer Production Line.

When producing the compound fertilizer, there are two points you should pay attention to. The first points is to batching the base fertilizers. The second points is to treat the mixed compound fertilizer. The detailed information about these two points is as follows.

Through noting the above two points, you can prepare the high-quality raw materials for producing the compound fertilizer. What’s more, there won’t be loss and damage of the straight fertilizer nutrients.

5 Reasons For Selecting SX Compound Fertilizer Production Line

The SX compound fertilizer production lines have been sold at home and abroad. Our customers have basically zero negative reviews on our production lines and production equipment. Why is SX compound fertilizer production line deeply loved by customers? The following five reasons may explain the question.

SX has engaged in producing the compound fertilizer equipment for many years. There are many skilled technical personnel and experienced customers service staff in SX. Therefore, we have the confidence to provide you with high-quality fertilizer production equipment and service.