The chicken waste processing machine prices are related to the their types and models. When turning the chicken manure into organic fertilizer, you need to buy many types of processing machines, such as dewatering machine, compost turners, granulator machine. They are on sale at the different prices. FPC company designs and produces a set of chicken waste processing equipment. There are powder fertilizer production machine, granular fertilizer production machine and liquid fertilizer production machine in FPC. All of them are sols at the affordable price. To get the specific chicken manure processing machine price, you know what types of machine are needed. You can know the price of chicken waste processing machines from the following.

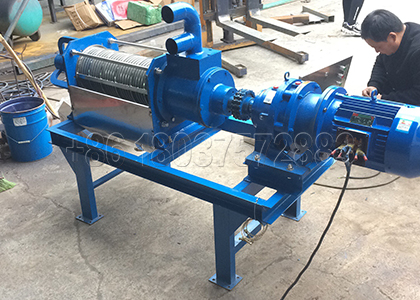

How much is the chicken manure solid liquid separator machine?

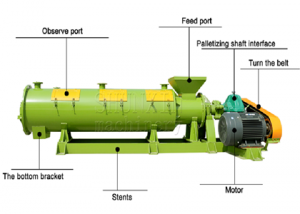

In order to treat the wet chicken manure, FPC designs and produces two types of solid liquid separating machines. One is inclined-sieve type solid liquid separator, and the other is screw-extrusion type dewatering machine. They are efficient animal manure dewatering machines. You can use them to lower the water content in chicken manure to 30%. In addition, they are on sale at the different prices. Then, how to choose the suitable chicken manure dewatering machine at the best cost? When your budget is limited and the amount of wet chicken manure is small, the screw-extruded dewatering machine is more suitable. When you want to get higher production efficiency, you can buy the inclined-sieving solid-liquid separator.

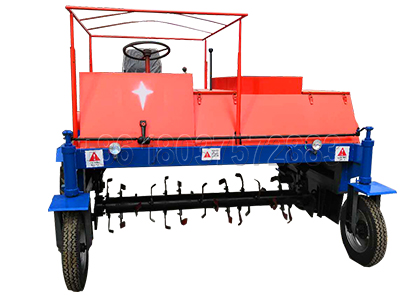

What is the price of chicken manure fermentation machine?

They are many types of compost turner machines for chicken manure fermentation. Their prices are different. For example, when your budget ranges from $5,000 to $15,000, you can buy wheel type or groove type compost turner for trough fermentation systems. When processing the chicken manure in windrow composting system, you can purchase crawler type and moving type compost turner. Here is also a fully automatic composting machine for sale in FPC company. You can make manure composting fully automatically and save invested manpower. The price of vertical fermentation tank is higher those of above compost turners. You can get suitable compost turning equipment at the best price in FPC company. Welcome to consultation.

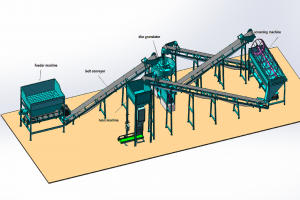

How to choose the chicken manure pellet machine within expected cost?

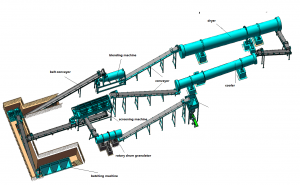

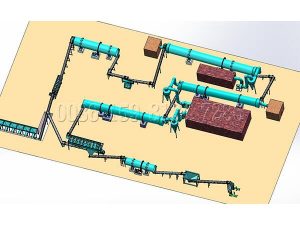

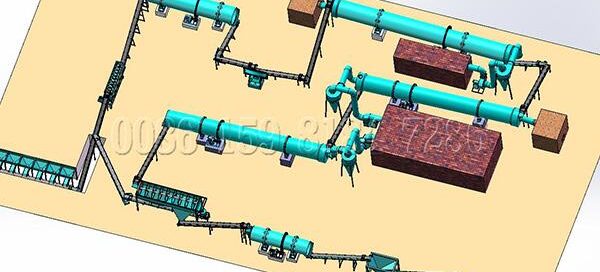

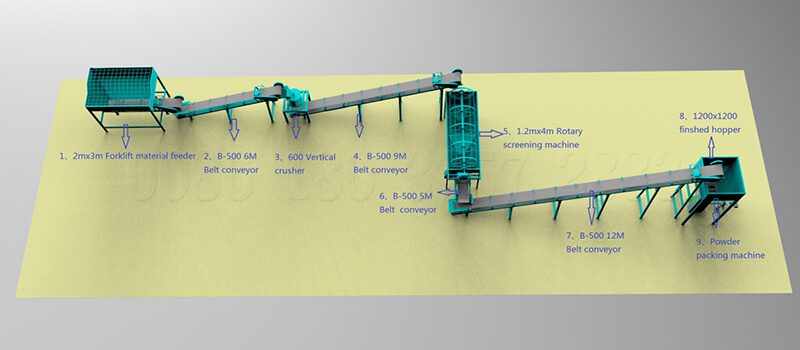

After composting completely, you can pack the powder composted chicken manure for sale. If you want to make more benefits, you can produce the powder chicken poop into granules. Then, what machines should I deploy for chicken manure granules production? Here are two main types of fertilizer granulators for you. They are wet granulator and dry granulator. A dry fertilizer granulation machine price is lower than that of wet granulation machine. When your budget is not abundant, you can select the dry granulation equipment. When applying dry fertilizer pelletizer, you can omit the chicken manure granules drying process and save investment. When producing 10-20tpd of chicken manure pellets, you can buy the rotary drum granulator. The price of chicken manure pellet machine is various. You can email us to get newest price list of chicken waste pellet machine.

To make pretty chicken waste pellets, what machines can I purchase?

For improving fertilizer pellets competitiveness , some fertilizer manufacturer would like to use granular polishing machine and fertilizer coating machine. The fertilizer polisher can make chicken manure more smooth and round. And the fertilizer coating machine can add beneficial bacteria and trace elements into the chicken manure granules. What’s more, you can also use the coating machine to dye the chicken manure pellets with different colors. From the above, you can know that they are two different types of fertilizer production equipment. Therefore, these two machines are sold at the different prices. The coating machine price ranges from $3,500.00 to $12,000.00. The fertilizer polisher are sold at the price of about $2,000. You can email us for details.

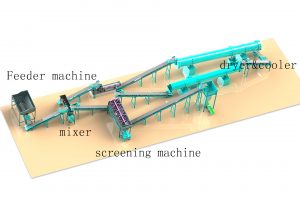

How much are machines in the chicken manure liquid fertilizer production line?

There is a new technology for chicken waste processing in FPC fertilizer equipment manufacturing plant. It is chicken manure liquid fertilizer production line. You can buy a whole set of chicken manure liquid making line at the affordable price in FPC company. Because different production lines of liquid fertilizer are sold at different prices. When starting liquid fertilizer production project, you can contact us to get the latest price list. As the same time, we can provide you with processional advice about production line design and installation according to your production needs. Welcome to consult.

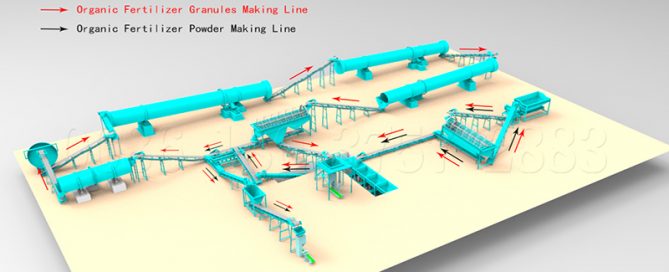

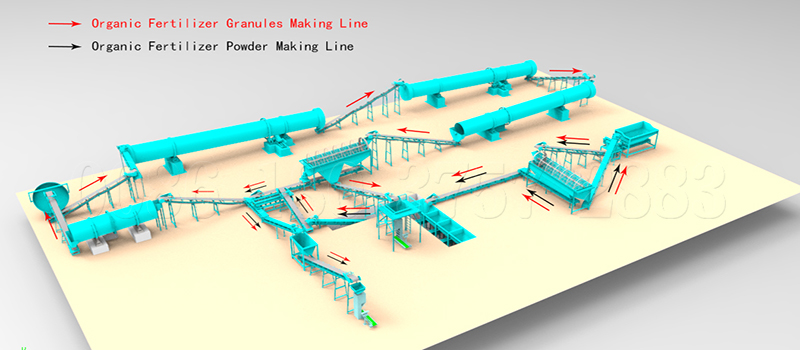

The above are the main chicken waste processing machines. There are also other fertilizer equipment for chicken manure processing like rotary drum dryer, fertilizer screening and fertilizer packing machine. If you need to use these machines, you can email us from our official website. Chicken waste processing machine price doesn’t depend on its type and technical parameters only. To a large extent, the price of chicken manure processing machine depends on the production capacity and site area of your fertilizer plant.

FPC is an old-brand fertilizer equipment production company. We have been dedicated in fertilizer equipment development and production over 15 years. We have the confidence to offer you quality chicken waste processing machine. Furthermore, when buying our machine of chicken manure processing, you can experience first-class service. For example, with many years of production experience, we can give you many processional suggestions and technical guidance.