Bulk blending fertilizer production line is to mix several unit fertilizers simply mechanically to form a kind of BB fertilizer. There are four steps in the BB fertilizer production process. The four steps are to select the base fertilizers, batch, mix and package the finished fertilizer. According to four-step process of BB fertilizer, you can consider to assemble the BB fertilizer production line from three aspects. The three aspects are the production scale, production site and your budget. SX BB fertilizer production line will be your best choice. Because there are many advantages of the sx BB fertilizer production line. For example, SX has fertilizer production equipment with unique structure designs. What’s more, we can provide the best service. By adopting SX fertilizer making equipment, you can produce required BB fertilizer. For the selection and maintenance of BB fertilizer production equipment ,we will give you some reasonable advice.

Because bulk blending fertilizer is a kind of fertilizer produced by simple mechanical mixing of several straight fertilizers. Therefore, the production process of bulk blending fertilizer is relatively simple. The bulk blending fertilizer production process can be summarized into four steps: selection of base fertilizers, accurate batching of raw materials, uniform mixing and finished product packaging.

To ensure the high quality of the BB fertilizer, you should follow the following three principles when selecting the base fertilizer for the BB fertilizer

The above three options for basic fertilizers are for one purpose. The purpose is to ensure that the fertilizer you produce is of higher quality. By selling the BB fertilizer with high quality, you can make more benefits for yourself.

Through the above mentioned four steps in the BB fertilizer production process, you can understand that the quality of BB fertilizer will be affected in many ways. We recommend you to use sx bulk blending fertilizer production line if you want to produce standard BB fertilizer efficiently. In addition , you can produce the high quality BB fertilizer with the sx BB fertilizer line .

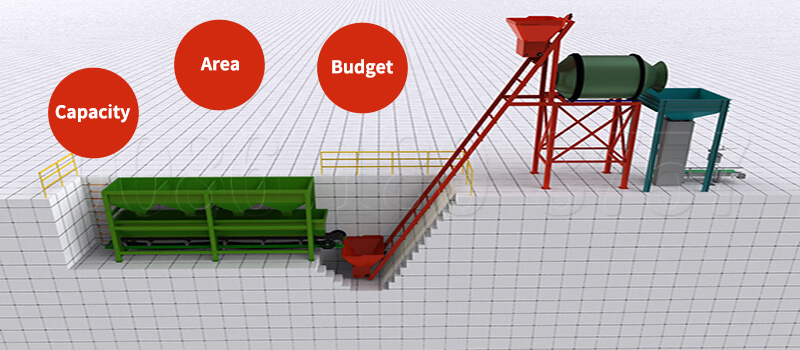

Three Factors That Determine The Assembly Of Bulk Blending Fertilizer Production Line

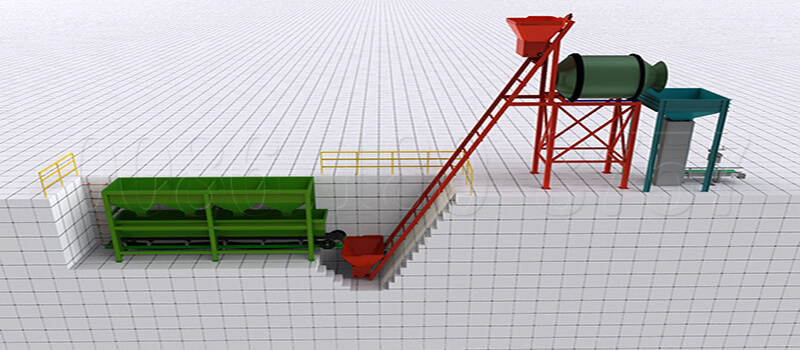

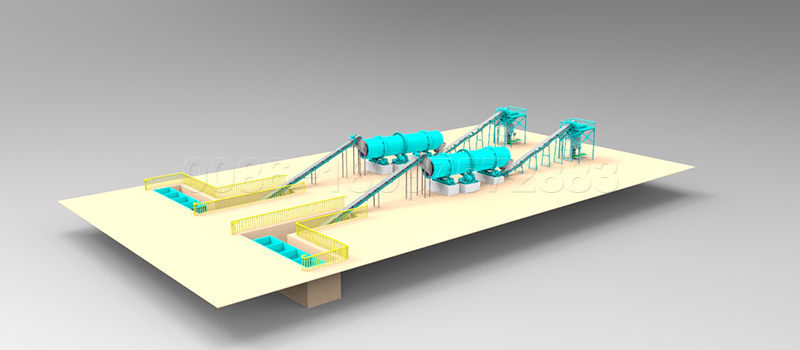

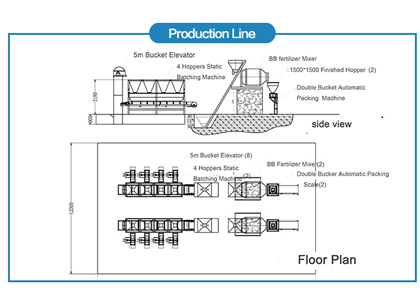

The above BB fertilizer production process shows that when assembling the bulk blending fertilizer production line, you need three BB fertilizer production equipment: batching system, mixing machine and packaging machine. However, each production equipment has different types and specifications. Obviously, the handling capacity, productivity and price of the BB fertilizer production equipment change with the type and technical specification.So, how to choose the most suitable BB fertilizer production equipment? You can mainly consider from the following three aspects.

The above mentioned three aspects can affect the establishment of your bulk blending fertilizer production line. The above contents are for reference only. Of course, you can provide us with the relevant data about your expected bulk blending fertilizer production process. We will provide you with reasonable advice to solve your problem.

Why The Sx Bulk Blending Fertilizer Production Line Is Your Best Choice?

Our bulk blending fertilizer production line is popular with domestic and foreign fertilizer manufacturers. The main reason is that we have done the best in many ways, such as the design and production of fertilizer production equipment, adaptability of production equipment to scientifically designed formulations, and so on.

Unique Design

Each machine used in bulk blending fertilizer production line is designed with a unique structure. These unique structural designs not only make machines more convenient to use, but also make the performance of these machines more stable. For example, our BB fertilizer mixer improves the precision of ingredients and overcomes the problem of stratification caused by different specific gravity and particle size of raw materials, thus improving the efficiency of stirring. Using our fertilizer production line can make you produce BB fertilizer stably and efficiently. Moreover, the raw materials of our production equipment have the characteristics of corrosion resistance and wear resistance, which can greatly prolong the service life of the machine. For instance, the mixing blade of disc mixing machine adopts special alloy material with high wear resistance.

High Adaptability

Because the BB fertilizers produced according to the scientific have many advantages, such as comprehensive nutrients. Therefore, all the fertilizer producer will manufacture the BB fertilizer according to the scientific formula. According to different soil conditions and the crop growth needs, the BB fertilizer production formulation can be various. Because of the varieties of fertilizer formulations, the BB fertilizer production equipment is required higher adaptability to the formula. High adaptability equipment can produce BB fertilizer in accordance with the formula ratio. The adaptability of Sx BB fertilizer production equipment can adapt many kinds of BB fertilizer production formulation.

The Best Service

For the bulk blending fertilizer production line, we are an established company with many years of BB fertilizer production equipment production experience. Thus, we have the determination and confidence to provide you with the most reasonable bulk blending fertilizer production line plan. And for the price, we will provide you with the most reasonable quotation for BB fertilizer production equipment. As for transportation, we work with the best logistics company to deliver the production equipment to your side as quickly as possible. For installation, our technicians will guide the installation of the entire bulk blending fertilizer production line. And technicians will also conduct special training on how to use the fertilizer production machines. Of course, we also have other special services, such as warranty , technical support and so on.

The above content is only part of our advantages. Since there have been cooperation with many BB fertilizer production plants at home and abroad, you can fully believe in the quality, pre-sale and after-sales service of our bulk blending fertilizer production line.

How To Design Formula for Bulk Blending Fertilizer Production Line?

If you want to your BB fertilizer more popular among the customers, what should you do? You should consider this question from many aspects. The acceptability of fertilizer will change with the change of soil conditions, crop types and fertilization time. Therefore, you need to consider how to make your fertilizer sell better from these three aspects.

From the above, if you want your BB fertilizer to meet the market needs, you have to consider many aspects. You can manufacture the required BB fertilizer by using the sx BB fertilizer production to make more benefit for you.

Three Principles For Selecting BB Production Equipment

When choose the equipment that constitutes the bulk blending fertilizer production line, what you should pay most attention to is the equipment applicability. How to choose the best and most practical BB fertilizer production equipment? Here are three device selection principles that help you to select the best quality BB fertilizer production equipment.

As mentioned above, BB fertilizer production equipment should have these three characteristics. According to these characteristics, you will get the satisfying BB fertilizer production machines .

How To Prolong The Service Life Of The Bulk Blending Fertilizer Production Equipment

As we all know, all mechanical parts without regular maintenance, there will be parts aging or damage. This situation in the production of BB fertilizer will lead to the stop bulk blending fertilizer production line and then affect the production efficiency. How to avoid this situation in BB fertilizer production? There are some ways you can adopt.

Regular Cleaning

After BB fertilizer production, the workers should clean the machine’s inlet, outlet and storage of materials. By doing so can not only avoid affecting the next production efficiency, but also avoid the damage of residual materials to BB fertilizer production equipment.

Fixed Lubrication

In the bulk blending fertilizer production line, there are many places will use bearings and conveyor belts. We need to lubricate these parts regularly. This can avoid the production error caused by Carton.

Fixed Maintenance

In order to ensure the normal operation of bulk blending fertilizer production line, you should regularly repair or replace some vulnerable parts.

Regular cleaning and maintenance are to make the bulk blending fertilizer production line operate normally. only the normal operation of production line can guarantee the capacity and the benefit of the factory. Therefore, these aspects still need to be paid attention to.

Error: Contact form not found.