Three Kinds Of Raw Materials For The $90,000 Organic Fertilizer Production Lines

In organic fertilizer production, there are many raw materials you can choose to produce the organic fertilizer. You choose the raw materials for producing the organic fertilizer mainly from these three aspects. The followings are for your reference only. As for selecting raw materials, you can also choose them after investigate the local soil conditions, organic fertilizer sales market and planted crop types.

As mentioned above, you can know about that there are enough nutrients in the animal manures. And you can produce the organic fertilizer and the liquid organic fertilizer by using the animal waste. But there are still some points you need notice. The reason why you need compost the raw materials is that there are many pathogenic bacteria in the animal feces. After composting, you can remove the harmful bacteria completely.

Green fertilizer is a high-quality organic fertilizer source. That is because all kinds of green manure plants contain high organic substances and many nutrient elements and micro-elements.

There are about 15% organic matter in the green manure plant. And the content of nitrogen will account for 0.3%-0.7% of fresh weight of the green manure. Legumes (such as alfalfa) are more abundant in nitrogen, about 0.3%-0.6%. Although there is high nitrogen content in the legume green manure, the content of phosphorus and potassium is relatively small, especially phosphorus.

Because after being composted, the green manure can support various nutrients for plants, the green manures are one of the most popular fertilizer among the customers.

Through the above, you can collect the organic fertilizer raw materials from three sources. But there are some problems of these raw materials. Therefore, you’d better use the fertilizer production equipment to treat the materials. In this way, you can make the organic manure with higher-quality.

How To Design The Organic Fertilizer Production Lines Within $90,000?

There is powder organic fertilizer, column shape organic fertilizer and spherical organic fertilizer in the fertilizer sales market at present. However, considering you want to set up an organic fertilizer production lines within $90,000, we suggest that you make the powder organic fertilizer. There are four steps of the powder organic fertilizer production process. You can refer to the following.

Composting Process Of Organic Fertilizer Production Lines

The composting is the first and important process for producing the organic fertilizer. Therefore, you should note many factors when composting. Before composting, in order compost normally, you should adjust the factors like moisture, pH of the materials which will affect the composting process. While composting, you should focus on the material temperature to adjust the composting stage and effect. In order to make composting better, generally you should flip the raw material to adjust the moisture and oxygen content by using the organic fertilizer composting machine.

Crushing Process Of Organic Fertilizer Production Lines

After composting, there are fewer organic matters in the raw materials than before. Moreover, almost all the organic substances are transformed. And the materials particles sizes also become smaller. However, there are still some inorganic matters like stones, plastic in the fermented organic fertilizer. Therefore, you should use the crusher to grind the bulk materials and the inorganic matters. By doing so, you can refine the organic fertilizer powder to make the fertilizer more beautiful.

Screening Process Of Organic Fertilizer Production Lines

After crushing, you will get the organic fertilizer with almost the same fineness. But in order to make the powder organic fertilizer have a better appearance, you need to screen the organic fertilizer powder. Then you can package it into powdered organic fertilizer with different fineness. When screening, you need to use the organic fertilizer screening machine. SX has various types of screening machines. We can recommend the most suitable multi-stage screening machine according to your budget of US $90,000.

Packing Process Of Organic Fertilizer Production Lines

In order to be convenient for storage and transportation, you need to package the powder organic fertilizer. During packing process, in order to save manpower, you can use the organic fertilizer packaging machine. By using the packaging machine, you can make the packaging process more automated. As a result, you can improve the organic fertilizer production efficiency. Because of poor ventilation or wet environment, the quality of powder organic fertilizer products will be affected. Therefore, you should pay attention to organic fertilizer storage place should have a dry and ventilated features.

As described above, the composting process is more important in the organic fertilizer production lines. But how can you compost the raw materials better? The followings can give you some useful suggestions.

How To Compost For The$90,000 Organic Fertilizer Production Lines?

As mentioned above, the organic fertilizer composting process can be divided into three stages: preparation, the first fermentation and the second fermentation

There are six steps you should do while preparing the organic fertilizer materials. The following detailed information can be your reference.

Adjust The Water Content

From the above two aspects, you could know that it is important to regulate the water content in the fertilizer raw materials. Therefore, you’d better use the solid-liquid separator to treat the raw material with high water content. In the end, after many experiments, the water content at 45%-60% is the most suitable for composting according to the weight of the raw materials.

Adjust The Materials C/N

Adjust Material Particles Size

While selecting the fertilizer crushing machine, you should still consider it from the economic aspect. Because the finer the crusher, the greater the power consumption, and the cost of processing materials will also be increased. For the 90,000-dollar organic fertilizer production line, you should choose some soft, perishable organic waste to produce organic fertilizer to reduce the cost of the energy consumption.

Adjust Materials pH Value

Adjust Organic Matter Content

Add Microbial Inoculants

Based on the results of extensive research at home and abroad, we will find the benefits of adding the inoculation agent to the material. You can know the further information from the following.

You can make the first fermentation in the open – air environment or in the fermentation device. But for the $90,000 organic fertilizer production lines, when composting, you can build the groove or pile the materials into the windrow in the workshop to make the first fermentation. Then the first fermentation includes heating stage, high temperature stage and cooling stages.

At the first fermentation stage, the decomposed substances such as cellulose have been decomposed by microorganisms. Then you need to make organic matters that aren’t decomposed undergo secondary fermentation. After secondary fermentation, organic matter will be further decomposed into stable organic matter such as humic acid and amino acid. Then how do you do the secondary fermentation?

Prepare For The Secondary Fermentation

Before the second fermentation, generally you need to pile the organic fertilizer materials up to 1-2m high. In this way, you can use the organic fertilizer composting machine to flip the material effectively.

While The Secondary Fermentation

During the secondary fermentation, it is important to supply sufficient oxygen and adjust moisture for materials. You’d better use the organic fertilizer composting turner machine to flip the materials regularly.

In summary, you can better compost the raw materials through the above methods. In addition, while producing the organic fertilizer, you also need to use organic fertilizer production machines to improve the efficiency of each process. From the following, you can know what kind of production equipment is suitable for the $90,000 organic fertilizer production lines.

The Composting Turner For The $90,000 Organic Fertilizer Production Lines

You can get about 20 tons powder organic fertilizer in an hour by running the $90,000 organic fertilizer production lines. Therefore, we recommend you choose the wheel type compost turner with high working efficiency. There are many high-quality wheel type composting turners in SX. You can refer to the following characteristics of the SX organic fertilizer wheel type composting machine.

The Large Flipping Span

Compared with the traditional compost turning equipment, wheel type composting turner machine has been improved greatly in the depth and span of flipping materials. Let’s discuss the span of flipping materials first. You can use the SX wheel type compost turner to compost the materials with the width of about 30m. By using the wheel type with large flipping span, you can improve the composting process efficiency.

The Deep Flipping Depth

We have also greatly improved the turning depth of the wheel type composting machine. The traditional organic fertilizer composting equipment can only flip the material pile with a depth of 1.8 m at most. By contrast, you can flip the materials with 1.5 m-3 m depth by using the wheel type compost turning machine.

Without Dead Angles When Flipping

There are two flip discs with large diameter on the SX organic fertilizer wheel type compost turner. When you compost materials with the wheel type composting turner machine, the device which can regulate the speed and the place on the machine will drive the two wheels to flip the materials in all directions. By doing so, you can compost the material completely.

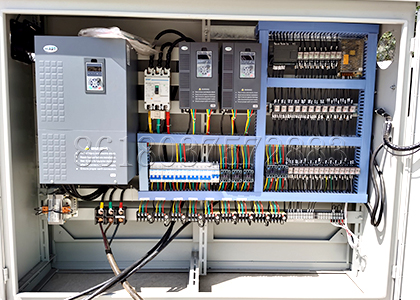

Highly Automated

We equip the wheel type composting machine with the fully automatic electric control system. Therefore, it is unnecessary to operate the composting turner by manual when the machine is working. You can save the manpower by using the trench composting turner.

Low Energy Consumption

There is an energy – efficient drive mechanism on the SX disc flip machine. By using an organic fertilizer large scale composting turner with this structure, you can save 70% energy than using the traditional compost turner when flipping the same amount of organic waste.

You will have the intimate knowledge of the SX wheel type compost turner machine from the above. In addition, you should know that SX wheel type trench composting turner is suitable for the groove type fermentation. Therefore, you should build the civil constructions for the composting process.

While Crushing, What Machines Can Be Used For The $90,000 Organic Fertilizer Production Lines?

For $90,000 organic fertilizer production lines, the vertical crushing machine is the best organic fertilizer crusher for you. There are many advantages in the SX organic fertilizer crusher. You can know about the detailed technical parameters from the following.

The above is about the structural characteristics of the SX fertilizer vertical crushing machine. There are also other shredding machine like chain-type crusher,semi-wet material crusher in SX. You can select the ideal crushing equipment for your organic fertilizer production lines.

For Screening Process, What Kind Of The Machine Can You Buy For The $90,000 Organic Fertilizer Production Lines ?

After crushing, there are still some foreign substances like plastics in the raw materials.Therefore, you need to use the screening machine to remove them. For the $90,000 organic fertilizer production lines, we recommend you buy the rotary drum screening machine.There are different types and specifications of the rotary sieving machine in SX. You can know more about the advantages of the SX rotary sieving machine from the followings.

As shown above, because of these advantages, there are many organic fertilizer manufacturers prefer to use the SX rotary drum screening machine. While purchasing the screening equipment, you’d better consider it based on the budget and organic fertilizer production lines capacity.

The Machine For The Packaging Process Of Organic Fertilizer Production Lines.

Considering the powder organic fertilizer production lines, we recommend that you choose the packing machine specially for the powder fertilizer. With the budget of $90,000, the single bucket automatic packing scale is suitable for you. There are different technical parameters of the single bucket automatic packing machine you can select in SX organic fertilizer equipment production base. Moreover, there are many advantages of our automatic packaging machine which is worth your choice. The specific advantages are as follows.

In addition to the above equipment, you need to purchase organic fertilizer production equipment and loader type feeder and belt conveyor to make your organic fertilizer line more complete and efficient. All of the above technical parameters are for your reference only. Because we usually modify some equipment and parts according to customer requirements. If you have demands, you can provide us with your requirements for organic fertilizer line design and equipment. And we will do our best to meet your reasonable requirements.

From the above, you can choose the right raw materials to produce the organic fertilizer. Then, you can know the detailed production process of the organic fertilizer. Third, you can know about how to compost the raw materials more efficiently. At last, you can select the right production machines for your $90,000 organic fertilizer production lines.