In the organic fertilizer production industry, fertilizer producers make different types of the organic fertilizer based on the different fertilization time. While with the budget of the $360,000, you can design the granular organic fertilizer manufacturing business plan. There are many advantages like less environment contamination, high utilization and sophisticated production process while producing the fertilizer granules. However, what should you do for running the granular organic fertilizer productions lines? You can ask us for help. We can give you some advice about how to operate the organic manure production lines and how to choose the right type of the production equipment. What’s more, we can also design the organic fertilizer production line and customize the equipment for you based on your requirements.

What Type Of The Organic Fertilizer Production Lines Can You Choose For $360,000 Manufacturing Business Plan?

In the organic fertilizer production industry, because the crops need different organic fertilizer at this different growth stages. According to this situation, organic fertilizer producers mainly produce powder and granular organic fertilizer. With the budget of $190,000, we recommend you to run granular organic fertilizer manufacturing business plan. Then what are the benefits of choosing granular fertilizer production line? From the following, you can know more about the fertilizer particles production process.

Because of these advantages of the organic manure particles production line, there are more and more organic fertilizer producers choose to set up the organic fertilizer granule manufacturing business plan.

How Do You Run The $360,000 Organic Fertilizer Manufacturing Business Plan?

There are a lot of factors to consider when you run the organic fertilizer manufacturing business plan. Because you need to invest many parts like equipment and the production site. For $ 360,000 organic fertilizer production lines, you can consider how you need to build the whole production line of organic fertilizer from the following.

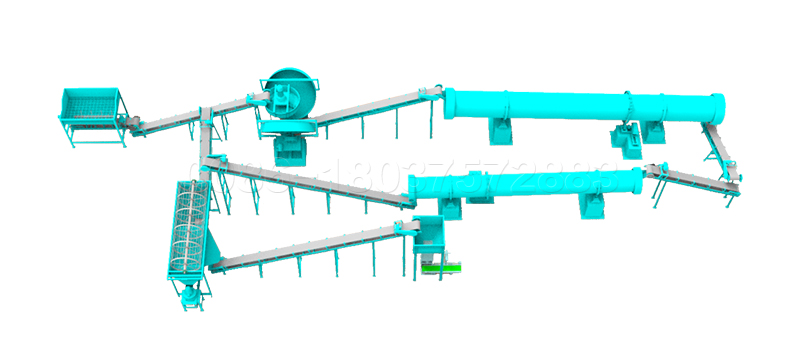

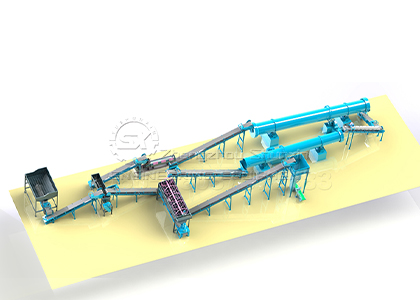

The Productions Equipment

At the different stages of the organic fertilizer production process, you will need to use the different types of fertilizer making machine. For reducing the cost of purchasing manufacturing equipment, you’d better choose the right machines based on your $360,000 organic fertilizer manufacturing business plan. Therefore, you can make full use of your investment fund to build the fertilizer making plant.

The Production Site

While choosing the making place for the organic fertilizer, you should note the distance. The first distance is between manufacturing site and the fertilizer raw materials supply place. In order to lower the transport charge, the fertilizer production site should be close to the raw material supplier. Another distance is from the production site to the residential area. The production site should be far away from the human living area.

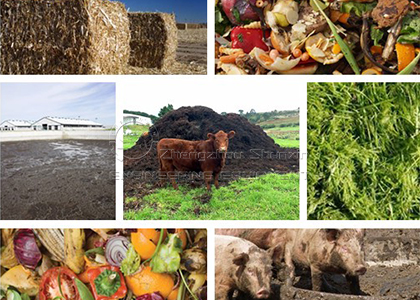

The Raw Materials

While preparing the organic waste, you should note the ratio of the raw materials to the organic fertilizer productivity. The amount of the raw materials should be the three times the production capacity of the organic fertilizer. For example, you can make 10 tons of organic fertilizer per hour while running the $360,000 organic fertilizer production lines. Therefore, you should prepare about 30 tons of raw materials for making the organic fertilizer.

The Invested Manpower

The manpower you should invest depends on whether you equip high-automated production equipment for your organic fertilizer production lines. For example, when composting the organic manure, you choose to use SX organic fertilizer fully automatic fermentation tank. You just need to employ one or two people to operate this composting machine. However, you will pay more for buying the high-automated production machines.

For managing the $360,000 organic fertilizer production line, if you do not know how, we will provide some reasonable advice for you. Our technical personnel can also design the production line for you freely and provide you with good quality and cheap production machinery according to your production plan.

How To Choose The Raw Materials While Designing $360,000 Organic Fertilizer Manufacturing Business Plan?

As mentioned above, the local soil nutrients content and the crop growth needs will effect the raw materials selections. Usually, you can collect the raw materials from the following two sources.

Animal Manure

Animal manure contains a lot of organic substances, nitrogen, phosphorus and potassium elements which plant needs at different growth stages.Therefore, animal manure is a particularly good organic fertilizer raw material. But some animal feces contain too high moisture such as cow dung. While producing the cow dung organic manure, you need a solid-liquid separator for the dehydration.

Agricultural Waste

The agricultural waste is an important kind of the organic fertilizer raw materials. You can use the agricultural waste for adjusting the C/N, pH and the moisture of the raw materials. By adding the agriculture waste into the raw materials, you can meet the requirements of the composting process. Therefore, you can shorten the composting period and accelerate the organic fertilizer production.

For producing the organic fertilizer, the organic waste collections are the first and important step. Thus, you should be clear about the kinds of the raw materials you can choose. In this way, you can lower the collection cost of the raw materials. What’s more, you can make use of the separated organic waste water to make the liquid organic manure. By doing so, you can earn more benefits for your fertilizer manufacturing plant. When you process the waste water, our company can provide you with the appropriate liquid-fertilizer formula and equipment to produce water-soluble fertilizer according to your local situation.

Before The Granulation, What Machines Do You Should Buy For Designing $360,000 Organic Fertilizer Manufacturing business plan?

Before the granulating process, you should prepare the composting machine, the crushing machine and the screening machine to process the raw materials. You can know about the detailed specifications of these machines from the followings.

The Composting Machine

For $360,000 organic fertilizer production lines, the crawler type compost turner is better for the composting process. SXLDF-3000 crawler type composting machine can turn 1500 m³ of raw materials per hour. What’s more, we install the working knife with diameter of 500mm for the SXLDF-3000 crawler type composting turner. Therefore, you can compost the raw materials more efficiently by using SX crawler-type compost turning machine.

The Crushing Machine

When building the organic manure production line with the budget of 360,000USD, you’d better choose the vertical crushing machine. Besides the advantages of less land occupation, the vertical type shredding equipment has another advantage of high working efficiency. For example, you can use the SXFLF-1000 new type vertical crusher to grind 8-15 tons of fermented organic materials in an hour. And its dimension is 2150mm*1220mm*2700mm.

The Screen Machine

The working efficiency of the SXGS-1870 rotary screening machine is suitable for the productivity of $360,000 organic fertilizer production lines. As mentioned above, through running this organic fertilizer production lines, you can make about 10 tons of organic manure particles in an hour. And the SXGS-1870 rotary screening machine can sieve 10-15 tons of materials. Therefore, we recommend you buy the SXGS-1870 rotary screening equipment.

The above data is for your reference only. There are other kinds and technical specifications of the fertilizer crushing machines, screening machines and composting machines in SX. There are multiple options of the organic manure production facilities for you in SX.

What Is The Best Granulation Machine For Running $360,000 Organic Fertilizer Manufacturing Business Plan ?

We have different kinds and specifications of the granulating machine. However, for the 360,000 organic fertilizer production lines, there are two types of the granulation machine you can choose from.

As for the other structure of the granulation machine, you can give us your organic fertilizer making program. We can modify the granulating machine based on your requirements.

After The Granulating Process, DoI Need To Buy Other Machines To Run The $360,000 Organic Fertilizer manufacturing business plan?

After the granulating process, you still need to process the organic fertilizer grinds to improve their quality. There are four steps you need to do next. Therefore, you need to buy other four machines for your production lines. You can learn about that from the followings.

Drying The Particles

After granulation, there is still 30%-35% of the water content in the fertilizer granules. In order to pack, store and transport these particles, you’d better reduce the moisture to about 10%. Therefore, you should use the dryer to lower the organic manure moisture. Considering the productivity of the $360,000 organic fertilizer production lines, we recommend you to buy the SXHG-1818 rotary drum drying machine. You can get 7-12 tons of organic fertilizer particles through using the SXHG-1818 rotary drum drier.

Cooling The Granules

There exists high temperature on the organic manure particles surface after drying. Because the fertilizer granules will be agglomerate due to high temperature, you need to cool them down. While cooling, we recommend you use the SX rotary drum cooler.The structure of SX cooling machine is the same as that of the dryer. What’s more, you can also remove the dust produced by collision among the particles. These dust will be recycled to granulate again. In this way, you can make full use of the fertilizer raw materials.

Coating The Grains

At this step, for improving the fertilizer particles competitiveness, you can coat them with bacteria agent or dye agent. At this moment, you could use the fertilizer coating machine. While using the coating machine, you should lay the pipes in the main body. The bacteria or dye agent will film the organic fertilizer pellets through the pipe. After being coated, the fertilizer grinds will have better fluidity. Therefore, it is convenient to keep in store and transportation. What’s more, the coated fertilizer will have a better effect for the crops.

Packing The Products

As for the packing process, you can use the automatic packing machine to make the packaging process more efficiently. There are many types of the automatic packing scales in SX. We select the advanced sensors at home and abroad while producing the automatic packing scales. Furthermore, there is an automatic compensation device on SX packing machine. Therefore, the machine can correct the error automatically. For the $ 360,000 organic fertilizer production lines, you can buy the double buckets automatic packing scales.

The technical parameters mentioned above are for your reference only. We can customize the fertilizer production machines for you. You can propose the requirements about the structure of the facilities. Then our technical personnel will design the machine structure freely for you. However, you need to pay more if you want to get the customized service.