For designing $140,000 organic manure manufacturing process, you’d better produce the granular fertilizer to make more benefits. The granular organic fertilizer production process is based on the powder ones. When finishing making the powder organic fertilizer, you should deliver the powder fertilizer into the granulation machine for granulation. After granulating, there are still some steps like drying, cooling and coating you should do. Therefore, you need to deploy many production machines while producing the granular organic fertilizer. However, how to choose the right type of production equipment? Actually, for selecting right equipment, you should consider the production capacity of fertilizer plant . Generally, $140,000 organic fertilizer production lines can produce 3-5 tons fertilizer granules per hour. You can choose the organic fertilizer equipment based on the data. You can also ask us for help. We can give you several suggestions about the equipment selections.

In order to make the quality products, you should be clear about manufacturing process of granular organic manure. Besides, you also need to know the what machines you should deploy at each step. You can know more about the organic manure manufacturing process and the fertilizer production machines from the following.

The composting process is one of important steps of the $140,000 organic manure manufacturing process. This step can be divided into two stages. The first stage is the preparation stage for composting, and the second stage is the composting stage. The specific process is as follows.

When composting the organic waste, there are some production equipment you can use. If there are high water content in some materials like cow dung, you can use the solid-liquid separator to remove the excess water. The composting turner machine will help you to meet the requirements such as oxygen content and temperature during the composting process. There are many types of the organic fertilizer composting machine in SX. Whether you adopt groove type fermentation mode or windrow one, we can provide the right type of compost turner based on your $140,000 organic manure manufacturing process.

For The Crushing Process,Why Should You Use The Vertical Crushing Machine For The $140,000 Organic Manure Manufacturing Process?

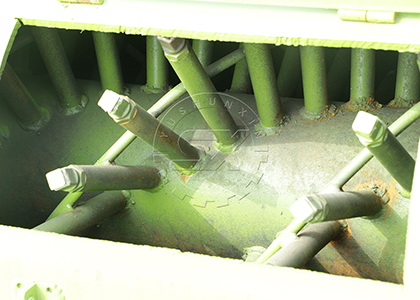

When starting the $140,000 organic manure manufacturing process, the new type vertical crusher is the best crushing machine for grinding the materials. There are different specifications of the vertical crusher in SX. Considering that you can produce 3-5 tons organic fertilizer per hour by running the $140,000 organic fertilizer production line, the SXFLF-600 new type crusher is more suitable for you. There are many advantages of the SX vertical new type vertical crushing machine. You can know more about the SX vertical type crusher from the followings.

High Efficiency

To improve the crushing efficiency,we have designed a compound structure which is consisted of the chains and blades. Therefore, you can crush the organic waste whose moisture is under 40% completely.

Stable Running

SX vertical crushing machine can operate stably. Because when crushing the organic manure, the crusher rotor is running stably. Thus, you can operate the vertical crushing machine stably without ground work.

Dust Prevention

To keep a better working environment, there is a dust removal device at the discharge port of the vertical crusher. With such dust prevention device, you can avoid the materials overflowing while crushing.

If you have some requirements about the vertical crushing machine structure, you can contact with us. Our technical personnel will offer the designing drawing of the vertical crushing machine to you. Also, we can customize the vertical crusher for you.

What The Granulation Machine Is Suitable For The $140,000 Organic Manure Manufacturing Process?

For granulating organic fertilizer, we recommend you choose the new type organic fertilizer granulation machine for your $140,000 organic fertilizer manufacturing process. Because the new type organic fertilizer granulation machine is not only suitable for the organic waste, but also suitable for crude fiber material like crop straw. There are many models of such a new type of organic fertilizer granulation equipment in SX. You can learn about the SX organic fertilizer granulating machine from the following.

The Machine Structure

The churning granulation machine can be divided into three parts. The first one is the body. The organic fertilizer will go through three stages inside the body of the granulation machine: mixing, granulation and polishing. The second part is the rotor part. The rotor of granulating machine is driven by motor and reducer of transmission device. The third part is the transmission part. Generally speaking, the transmission part and the body part are fixed on the same rack. In this way, it can not only ensure that the granulation machine has a strong structure, but also ensure that you can run the machine smoothly and stably.

The Granulating Process

When the stirring-teeth fertilizer pellets making machine is operating, the belt conveyor will deliver the powder organic manure into the machine. After the organic materials are into the granulation machine from the feed inlet, the rotor will do continuous rotation and mechanical movement with the casing. In this way, the powder material inside the machine will forms particles gradually. The mechanical agitation force and the friction will be the main power for powder fertilizer to form particles. If the particles meet the manufacturing process requirements.The final product particles will be discharged from the discharge port of the machine.

We have also selected the constituent materials of each part of the granulating machine strictly. In addition, the ball formation rate of our pelletizing machine can be up to 93%. Therefore, you can choose the new organic fertilizer granulation machine produced by SX safely. If you ask us about the pelletizing equipment, we will reply to you as soon as possible.

Why Do You Need The Drying And Cooling Machine For $140,000 Organic Manure Manufacturing Process?

After the granulating process, you should deliver the organic fertilizer granules to the drying machine and the cooling machine. Why should you do that? What benefits will you get from doing that? You can know about the answer from the following.

- In order to meet the packing requirements, you should remove the extra moisture in the pellets and improve the pellets strength. By doing so, you ca prolong the storing time of the granular organic fertilizer. You can learn the specific reason and process of drying from the following.

- After drying, these is a high temperature on the surface of the fertilizer pellets. And the fertilizer granules may be agglomerated due to water vapor generated by high temperature. Thus, you need to cool the fertilizer particles. You can know more benefits about the cooling process from the following.

Through the mentioned above, you can be clear about the reason of using the drying and cooling machine while making the granular organic fertilizer. After these two processes, you can improve the quality of the fertilizer pellets. For improve the drying and cooling efficiency, SX produces the rotary drying machine and rotary cooling machine. You can deploy the right type of the machine based on the production capacity of your fertilizer plant.

Why Should I Screen The Fertilizer In The $140,000 Organic Organic Manure Manufacturing Process?

In the production process of the organic fertilizer, you should use the screening machine to screen out the qualified fertilizer. There are two purpose for the screening process. You can learn more about the screening process from the following.

From the above, you can know that the purpose of screening process is to get the organic fertilizer granules products with higher quality. Therefore, for your $140,000 organic fertilizer production lines, you need buy the screening machine to sieve the materials and fertilizer. There are many specifications of the screening facility you can choose from based on your production capacity in SX.

What Types Of The Packing Machine Is Suitable For Your $140,000 Organic Fertilizer Production Line?

The packing process is the last step of the organic fertilizer production process. To make the packing process more efficient, you can choose SX automatic package scale. There are different types of packing machines in SX. You can learn about the technical parameter from the following.

The Single Bucket Automatic Packing Scale

SX single-bucket packaging machine has characteristics of dust proof, cold resistance, corrosion resistance and high precision. Its packaging speed is 4-6 packs per minute. Our packaging scales are highly accurate. For packing scale, we use advanced sensors to maintain the packing machine accuracy at about 0.02%. In addition, our packaging machine also features a wide range of weighing. You can pack a bag of 10kg-50kg of organic fertilizer granules.The Double Buckets Automatic Packaging Scale

The scale, control system, conveyor and sealing device consist of the SX double buckets automatic packing machine. The weighing range of the packing machine is from 20 kg to 50 kg per pack. Therefore,You can pack about 800 packs granular organic fertilizer in an hour. When using the double bucket packing machine, you will cost 1 kw electric power each hour. Therefore, the low energy consumption is another advantage of our double bucket automatic packing machine.As for how to choose the right type of the automatic packing machine, you can consult us for the detailed information. We will recommend the suitable type of the packing scale for your production lines.

SX has been engaged in making the fertilizer production equipment for many years. We can not only provide you with high-performance organic fertilizer production facilities, but also give you some reasonable suggestions about setting up $140,000 organic fertilizer production line.