When running organic fertilizer production lines, you must think about the organic manure making machine price. While thinking about the price, you should be clear about it varies with the type of machine and technical parameters. There are some factors which affect the organic manure making machine selection, such as raw materials type and produced organic manure type. We, as an organic fertilizer machines producer with years of experience, can supply many reasonable suggestions about fertilizer making machines selection for you. For $110,000 organic fertilizer production lines, it is more suitable for you to produce organic fertilizer granules. Before buying processing machine, you should understand granular fertilizer production process. You should know deploy what kind of machines at each step. After that, you could contact and tell us about your organic manure production project. We will provide you with qualified and suitable organic manure making machine at the best price.

In the organic fertilizer production industry, fertilizer manufacturers produce two types of the organic fertilizer according to the crops growth needs in different stages. Therefore, there are two kinds of organic fertilizer making processes you can select. One is the powder organic fertilizer production process, the other is the granular organic fertilizer production process. According to the budget of $110,000, you will earn more benefits from making the granular organic fertilizer than producing the powder one. Thus, you’d better select to make the granular organic fertilizer.

What is the specific production process of granular organic fertilizer? It can be divided into three parts: before granulation, while granulation and after granulation.

This stage mainly includes the materials preparation, materials composting, fermented materials crushing, screening after crushing and final batching.

After batching, you should use the fertilizer blending machine to make the nutrients distribute evenly before granulation. While granulation, the belt conveyor will deliver the mixed powder organic fertilizer into the granulation machine. Then the pellet making machines will adopt the dry granulation or wet granulation to make the powder organic fertilizer into ball shape. At this stage, you could also use different types of the fertilizer granules making machines based on your fertilizer production plan.

Through the above, you will know more about the granular organic fertilizer production process. Compared with the production of powdery organic fertilizer, the production technology of granular fertilizer is more complex. Moreover, you should buy many organic manure processing machines. But in the long run, you can get more benefit from producing the granular organic fertilizer. That is because of higher market benefits of granular organic fertilizer. you will get more information about the processing machines of organic manure from the following.

In order to make fertilizer more effectively, you should make use of organic manure making machine. At different stages of the organic manure production process, you may use different types of processing machines. From the following, you can know what organic manure making machine you need to purchase at best price.

What Organic Manure Composting Equipment At The Best Making Machine Price?

When composting the organic manure with the compost processing machine, you can choose the machine from SX. Considering that your budget is $110,000, the crawler type compost turning machine is suitable for your organic fertilizer production line. The specific technical parameters are as follows.

The above data is for your reference only. You can choose the most suitable crawler composting machine according to your fertilizer production project. If you want to choose other organic fertilizer composting machines, we also have walking composting machines and groove type compost turner machines for you to choose from. We will provide you with the suitable manure compost processing machine at perfect price according to your budget,

What Manure Granulation Machine Can I Get With Suitable Price For The $110,000 Organic Fertilizer Making Factory?

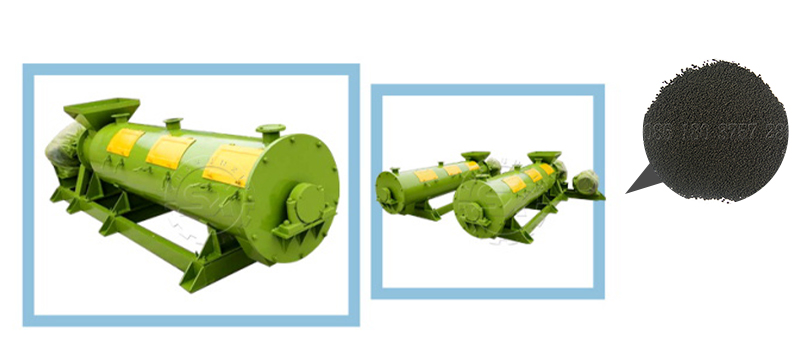

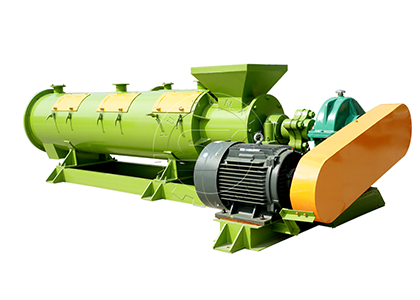

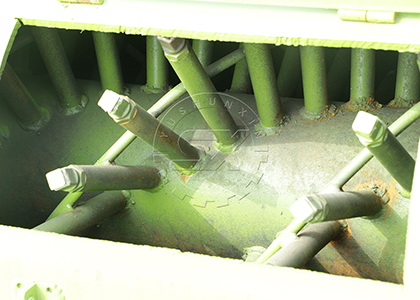

For Producing the organic fertilizer, SX designed and produced a new type organic fertilizer granulation machine. It can also be called stirring-teeth granulation machine. There are many advantages on the new type organic fertilizer granulation machine produced by SX. You can see the following:

In the SX organic fertilizer equipment production base, there are many models of stirring teeth granulation machine. You can granulate 1-8tons organic fertilizer granules per hour by using the new type organic fertilizer granulator. When running the $110,000 organic fertilizer production line, you can produce 1-2tons organic fertilizer particles per hour. You can choose the suitable manure stirring-teeth granulation processing machine at fair price. Or you can consult us and we will provide you with reasonable suggestions.

What Organic Manure Making Machine Should You Buy With Suitable Price After Granulating?

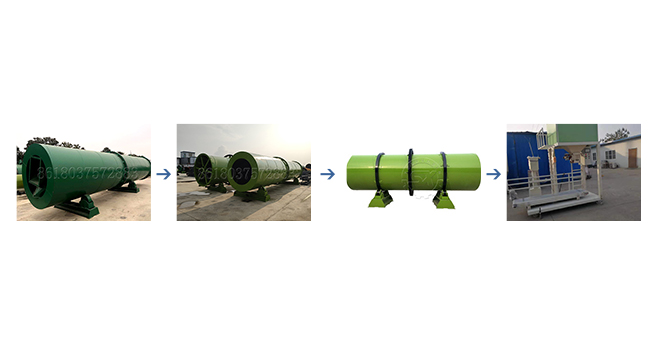

After granulating process, in order to improve the strength and reduce the moisture, you should dry and cool the organic fertilizer granules. If you need to dry and cool the organic fertilizer, we recommend you select the SX rotary drum drying machine and rotary drum cooling machine. Because there are many structural and technical innovations on our drying and cooling facility. From the following, you can learn more about the innovations.

Through the above, you may know more about the SX rotary drum cooling and drying machine. When starting the $110,000 organic fertilizer granules production line, you can contact with us. We will recommend the suitable type of the cooler and dryer to you.

After Buying The Machine At Perfect Price, What The Advantages Will I Get From Organic Manure Coat Making Step ?

There are many organic fertilizer manufacturers to coat the fertilizer at home and abroad. For the $110,000 organic fertilizer production lines, what benefits will you get after coating the fertilizer? You can know that from following.

Supply The Sufficient Nutrients

When producing the bacterial organic manure, you can use the fertilizer coating machine to film the pellets with bacteria agent. What’s more, the nutrients will be kept in the organic fertilizer granules after the coating process. Therefore, the coated organic fertilizer pellets can provide the crops with sufficient nutrients.

Easy To Store And Transportation

After coating, there is a better fluidity of the organic manure granules. Therefore, you don’t worry that the fertilizer particles will be broken and agglomeration during the storing and transporting process. Furthermore, you can also ensure the quality of the coated fertilizer grinds.

In addition, it is worth mentioning that the organic fertilizer after coating can be suitable for mechanized fertilization, which can improve the fertilization efficiency of farmers. This advantage also improves market competitiveness for the organic fertilizer granules you produce.

What Auxiliary Organic Manure Making Machine With Fair Price Do I Need For Running The $110,000 Organic Fertilizer Business?

In order to make the $110,000 organic fertilizer production line more complete, you’d better buy some auxiliary fertilizer facilities. What are these auxiliary equipment? The following can be your references.

Loader Type Feeder

The loader type feeder produced by SX has high working efficiency. That is because there are uniform discharge device, anti-blocking mixing device and anti-blocking vibration device. Therefore, when you are using our forklift feeder, you can either produce at uniform speed or without worrying about the machine being blocked by material.The Batching System

There are dynamic automatic batching machines and static batching machines in SX. These two automatic batching systems can complete the batching of the materials precisely based on the organic fertilizer formula you produce. By using SX automatic batching machine, you can save the invested manpower while matching the materials.The Screening Machine

In the granular organic fertilizer production line, you will use the screening machines twice. The first screening is to screen out the impurities in the crushed materials. And the second screening is to filter out the particulate fertilizer that does not meet the production requirements and send them back to the superior granulation process.The Belt Conveyor

By using the belt conveyor, you can get more smooth and higher efficiency of your organic fertilizer production line. At the same time, we equip the belt conveyor with the device which can prevent the powder fertilizer from flying. With such structural design, you can make full use of the materials and increase the yield of organic fertilizer.The auxiliary equipment can make the organic manure production machine more perfect. By deploying these fertilizer production machines, you can improve your organic manure production lines efficiency and make it more automated.

As mentioned above, you can set up a granular organic fertilizer production line with the budget of $110,000. If there are still some questions about the machines and production process. You can contact with us. We will respond to you as soon as possible. If you have some special requirements about the machines structures, we can design the machines drawings for free. You will get the organic manure processing machine at the best price from us. Besides, you can experience more high-quality service like customized service from us.